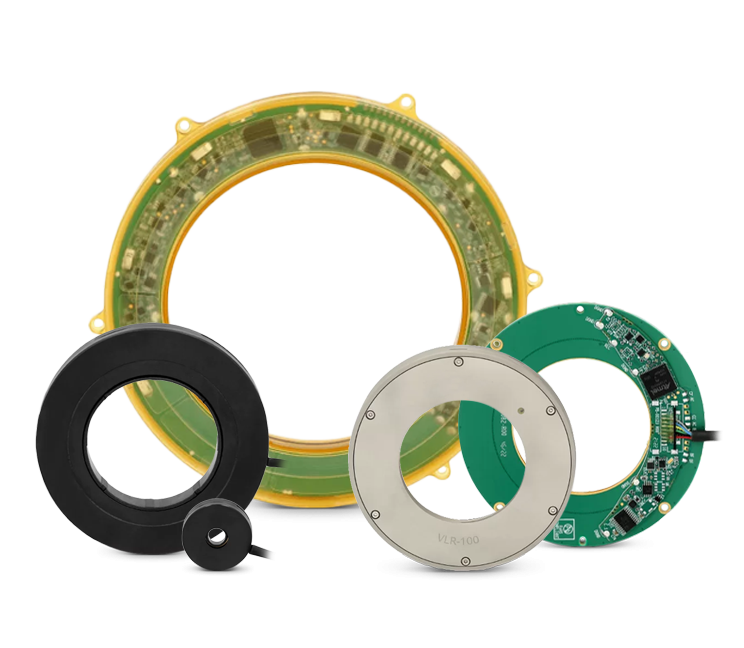

Versatile High-Performance Absolute Rotary Encoders

Our high-performance absolute rotary electric encoders combine precision and reliability for applications in harsh environments, medical, factory automation, and space.

Designed with a compact, contactless configuration and hollow shaft, they minimize axial space while offering outstanding durability. The series provides a range of sizes to meet diverse technical requirements.

These encoders feature zero magnetic signature, EMI/RFI resistance, low weight, low inertia, and an ultra-thin profile (≤10 mm), making them ideal for industrial automation, robotics, surveillance, military, defense, and avionics.

With exceptional shock and vibration resistance, the innovative electric encoder technology ensures high accuracy and extreme reliability in even the most demanding environments.

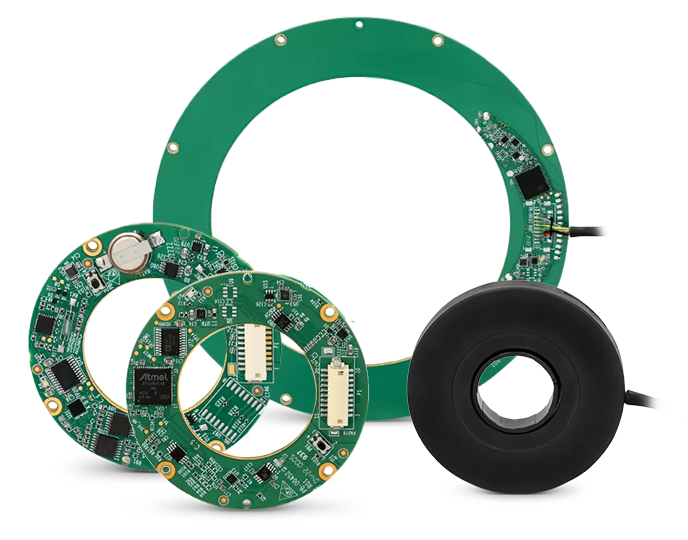

High-Performance Encoders for Harsh Environments

The DS-Serie, VLR-Serie, and VLP-Serie are designed to meet the demands of harsh environments, including space, avionics, and defense applications. These models comply with EMC standards IEC 6100-6-2 and IEC 6100-6-4, and operate within a temperature range of -40°C to +65°C. With the ability to withstand up to 98% relative humidity (non-condensing), they offer robust performance with 100g shock endurance for 11 ms and 20g vibration resistance across 10 to 2000 Hz.

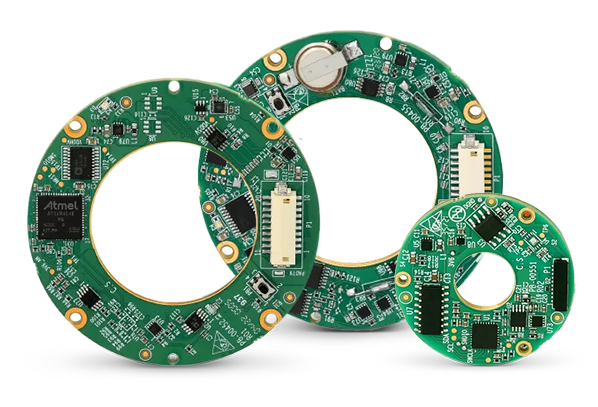

Cost-Effective OEM Position Sensors for Industrial Automation

The VLX-Serie and VLM-Serie encoders offer cost-effective OEM position sensors, designed with advanced Q-Core processing for industrial and medical robotics, automotive, and industrial automation applications.

Built to withstand demanding environments, these encoders comply with EMC standards IEC 6100-6-2 and IEC 6100-6-4, and operate in temperatures ranging from -25°C to +65°C.

They are resistant to up to 98% relative humidity (non-condensing), with shock endurance of 100g for 11 ms and vibration resistance of 20g across 10 to 2000 Hz.

Encoders for Robotics, Medical, and Surgical Applications

The DS-Serie, VLX-Serie, VLP-Serie, and VLM-Serie encoders are designed to meet ISO 13485 standards for medical devices, providing the reliability, accuracy, and resistance to surgical energy required for advanced medical robotic applications.

These encoders are engineered to withstand a range of demanding environments, offering robust performance with compliance to EMC standards IEC 6100-6-2 and IEC 6100-6-4. They operate within a temperature range of -25°C to +65°C and are resistant to up to 98% relative humidity (non-condensing).

With shock endurance of 100g for 11 ms and vibration resistance of 20g across 10 to 2000 Hz, they ensure exceptional durability in medical, robotics, and surgical applications.

Overview of The Electric Encoder

Our Precision Position Sensors, originally engineered for harsh environments, now serve a wide range of industries including defense, aerospace, homeland security, and motion control.

These rotary electric encoders—available in both standard and custom designs—also support medical, automotive, and other demanding applications. Using non-contact technology, they detect displacement through a space/time-modulated electric field for precise and reliable performance.

- Simple, robust design with minimal failure risk

- Low weight, inertia, and profile (≤10 mm)

- Absolute single-turn position output

- Accuracy up to 0.001° in select models

- Immune to magnetic fields and EMI/RFI

- Ultra-high-speed options with low latency

- Compatible with standard position feedback protocols

Frequently Asked Questions

How does the Electric Encoder™ differ from the incremental, pulse counting, or other logic level output, optical encoders?

The Electric Encoder provides the absolute position and its continuous, exceptionally smooth output signals proportional to the SIN and COS of the measured rotary (or linear) displacement. Rather than directly encoding the displacement it leaves the encoding task to the A/D converter and software optimized for it.

Is it similar to optical Sine/Cosine encoders?

Only in providing high resolution, but there are three main differences: its “holistic” nature, its much lower profile and its significantly simpler, more durable, construction. Also it has significantly less electric cycles per evolution (EC/R).

Is the output of the Electric Encoder absolute?

Yes, the output signals convey the absolute rotary (or linear) position without any movement.

How else does the Electric Encoder differ from the optical Sine/Cosine encoder?

Thanks to the relatively low number of EC/R the output signals are confined to the low end of the frequency spectrum and are less prone to errors due to PWM noise. The absence of temperature, or time, degradation mechanisms ‐ ball bearings, LEDs, etc. virtually eliminate any failure mechanisms.

Is it also unique mechanically?

Yes, the rotary Electric Encoder high accuracy is exceptionally unaffected by shaft eccentricity and tilt, as in high accuracy optical encoders, and therefore needs no bearing of its own for aligning the rotor relative to the stator, as a result it is directly mountable on the host shaft. The absence of internal bearings not only makes its profile low, but also obviates the need for a flexible shaft coupler, or flexible stator mounting, as a result the Electric Encoder provides both accuracy and compactness.

Is it suitable for space applications?

Yes, the following advantages make it space compatible:

- Low weight

- Low profile

- Low power consumption

- Wide temperature range

- Mechanical robustness

- Low outgassing

- Vacuum compatibility

- High reliability

- Radiation tolerant

Our Electric Encoder technology is currently incorporated in several space-related systems.

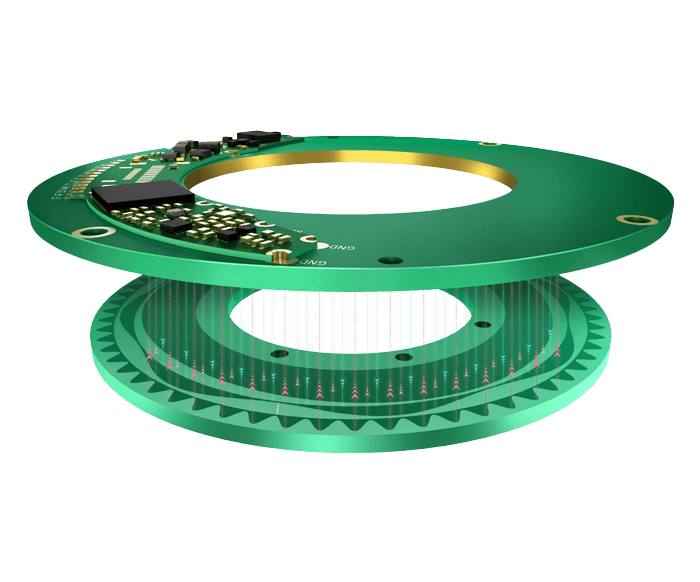

What actually happens inside the rotary Electric Encoder?

An internally generated space/time-modulated electric field interacts with a rotor which is made of a dielectric composite material. The rotor includes a peripheral sinusoidally shaped 3D pattern that serves the Fine channel, and a recessed sinusoidal pattern that serves the Coarse channel. The electric field is integrated over the full rotor area (hence “holistic”) and the resulting signal is processed and separated into Sine and Cosine output channels. Since the common channel processes both the Sine and Cosine outputs, they are nearly matched and the decoded angle is stable over time and temperature.

What is the resolution of the Electric Encoder?

The inherent resolution is virtually infinite, because of the continuous outputs. In practice, the resolution in bits/360° is N+M+1 where N is the binary representation of the number of amplitude quantization steps in the A/D converter and M is the binary representation of the number of Fine channels EC/R.

How does the Electric Encoder perform over temperature?

The operating temperature range may reach -55º C to +125º C (it can be extended to +150º C for short periods). The main reasons for this robustness are:

- The “holistic” rotor averages out the effects of minor mechanical deformations that occur at extreme temperatures

- The common processing channel for the Sine and Cosine signals. This makes electronic components’ tolerances and stability nearly irrelevant

- The immunity to internal offset voltages due to AC operation.

What about repeatability and accuracy?

The output reading will repeat itself to within +/- 1/2 LSB, either for position move-and-return or power-up. The accuracy increases as the number of EC/R increases. With properly corrected parameters an error as low as 10 arc seconds or below can be achieved.

How about RFI emissions?

The Electric Encoder conforms to CE directives.

How about RFI/EMI susceptibility?

The Electric Encoder is inherently immune to magnetic fields, internally shielded from electrical fields, and is also insensitive to RFI as evidenced by many defense applications.

How does the Electric Encoder perform in shock and vibration environment?

Very well, since it integrates signals over the entire rotor area, averaging out vibration effects. It is being used in demanding defense applications.

What is the Electric Encoder about?

In Electric Position Sensing angular displacement influences a patterned electric field that is continuously measured to provide position feedback. This technology can be regarded as a rare breakthrough where practically every imaginable performance parameter improves, compared with existing technologies at no compromise.

What does "holistic" encoder mean?

The Rotary Electric Encoder uses the whole physical area of the rotor at any time, unlike the optical encoder which uses only a small section of the rotor. In addition, the sine and cosine output signals are generated and processed in a common channel and are very pure and tightly matched. The result is insensitivity to mechanical assembly, vibrations, and installation errors as well as to temperature and contaminant effects. Contrary to logic, the correlation between high measurement accuracy and construction precision is no longer valid.

What is an ECR?

The number of Electrical Cycles per mechanical Revolution that the electric encoder provides as an output.

What is the MTBF of the Electric Encoder?

The Electric Encoder is made of a special polymer and includes low-power electronics (typically less than 50mW power consumption). It does not include components such as bearings or LEDs. Therefore, it has virtually no failure mechanism.