Solutions for Marine Offshore Cranes

Our crane slip ring offers extensive flexibility, enabling modification in voltage, amperage, and cable size to match your specific transmission requirements. Certified and tested, our products meet industry standards, ensuring reliable performance. Additionally, our solutions offer customizable signal transmission features for comprehensive control and monitoring.

- Options for voltage, amperage, and cable size.

- Certified and tested to meet industry standards.

- Separate chambers for critical power supply.

- Fully modifiable features for signals, data protocols, and more.

- Integration of fiber optical rotary joints supporting single mode (SM) and multi-mode (MM) fibers, with up to 32 channels.

If you’re seeking reference points, we encourage you to explore our past projects involving offshore cranes. You may find exactly what you’re looking for or a solution closely aligned with your needs. Moreover, we offer modifications to our existing models, providing cost savings compared to starting from scratch.

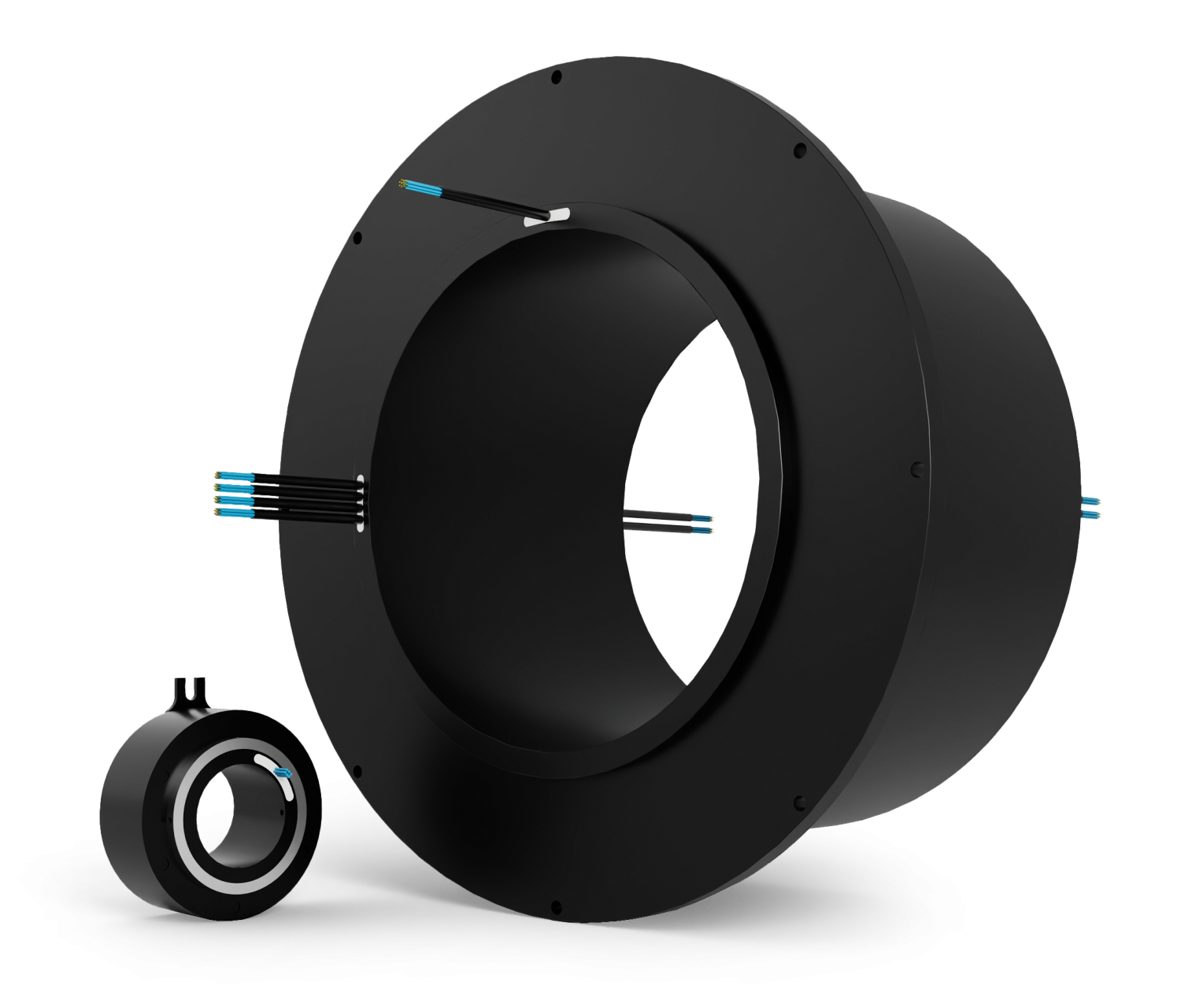

Hollow Shaft/ Through Bore Slip Ring Solutions

Our larger hollow shaft models are designed for seamless power and signal transmission, delivering reliable performance.

For cranes where the motor is placed inside the crane pedestal, the cardan shaft of the motor need to pass inside the slip ring up to the hydraulic pump motors. With our hollow shaft design, our slip ring ensures transfer of the auxiliary power and all control and data signals. Most of these slip rings can also offer 1Gbit ethernet transfer.

With the possibility of designing the slip ring with an inner diameter up to Ø900mm our hollow shaft slip ring solutions are a perfect fit for marine offshore cranes.

Discover our Hollow Shaft Slip Rings

Talk to us to learn more