Fully Modifiable Slip Rings

At Penlink, we provide high-quality slip rings that ensure reliable and efficient performance across industries like automation, energy, defense, and medical technology.

Our standard slip rings are built for durability and versatility, and we offer flexible options to tailor them to your specific needs. Our team is here to help you choose and adapt the right solution for seamless integration into your application.

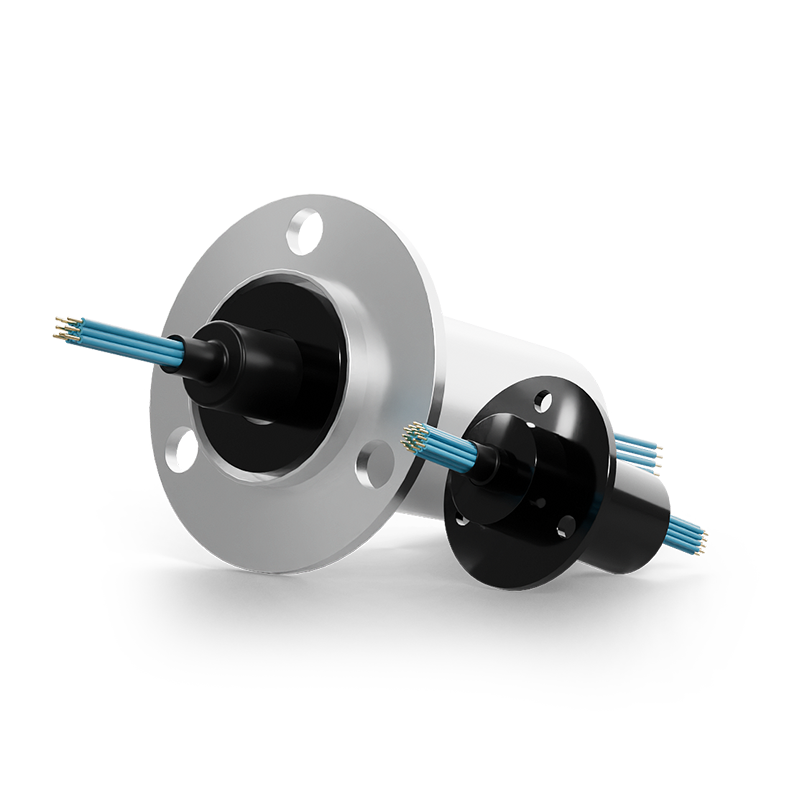

Compact Slip Ring Series

Our X12-X25 Compact Slip Rings are precision-engineered to deliver uninterrupted signal and data transmission, even in the most demanding environments. Designed with gold-gold contacts for superior conductivity and longevity, these slip rings ensure low electrical noise and extended durability for consistent, high-performance operation.

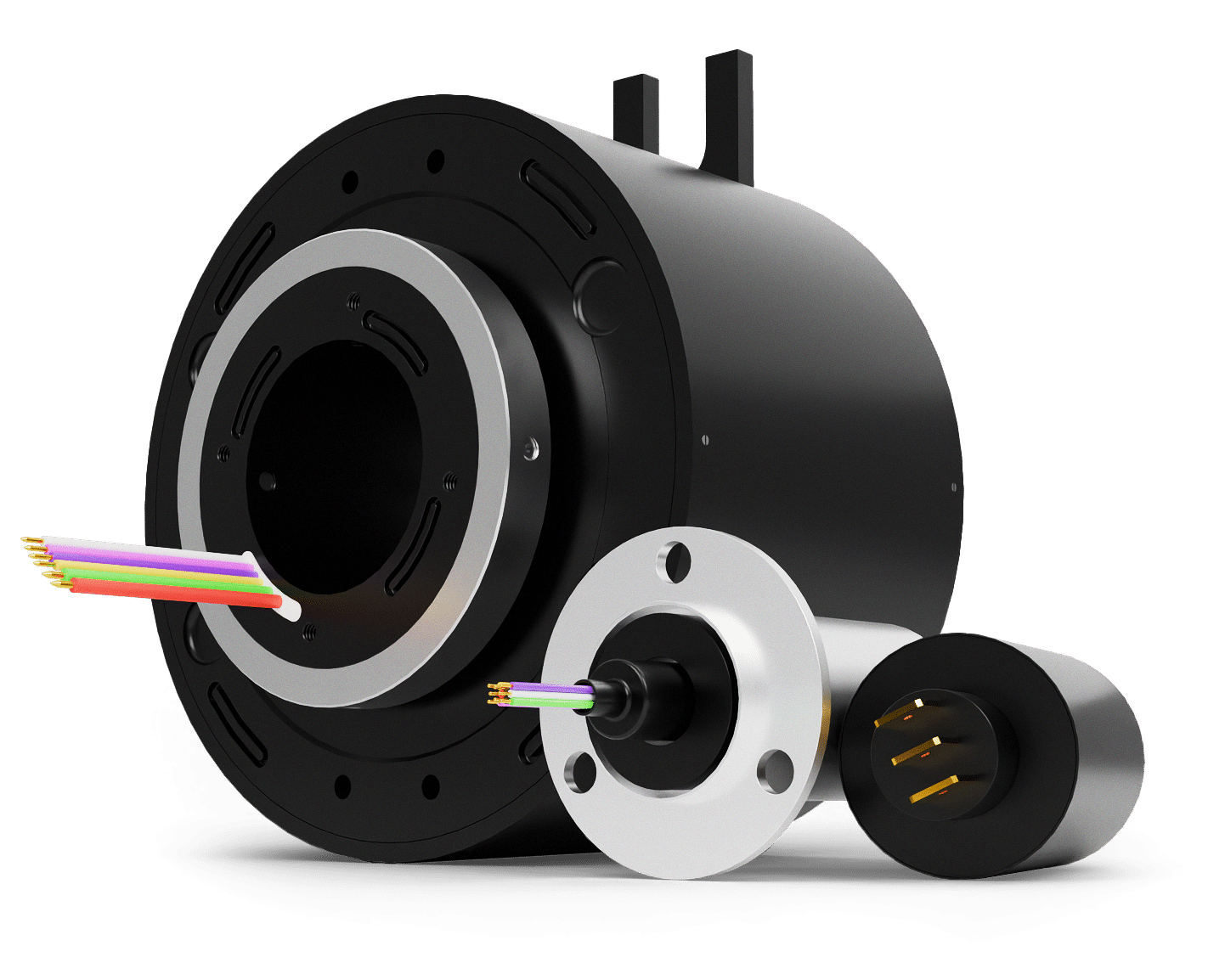

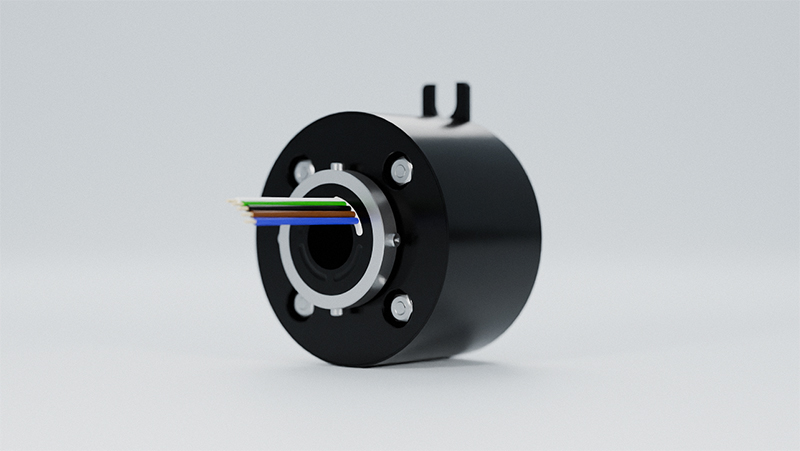

Hollow Shaft Slip Ring Series

Experience seamless signal and data transmission even during full 360° rotation, thanks to our cutting-edge fiber brush technology. Our slip rings require no maintenance or lubricating oil, ensuring hassle-free operation. With low torque and smooth rotation, they deliver reliable performance.

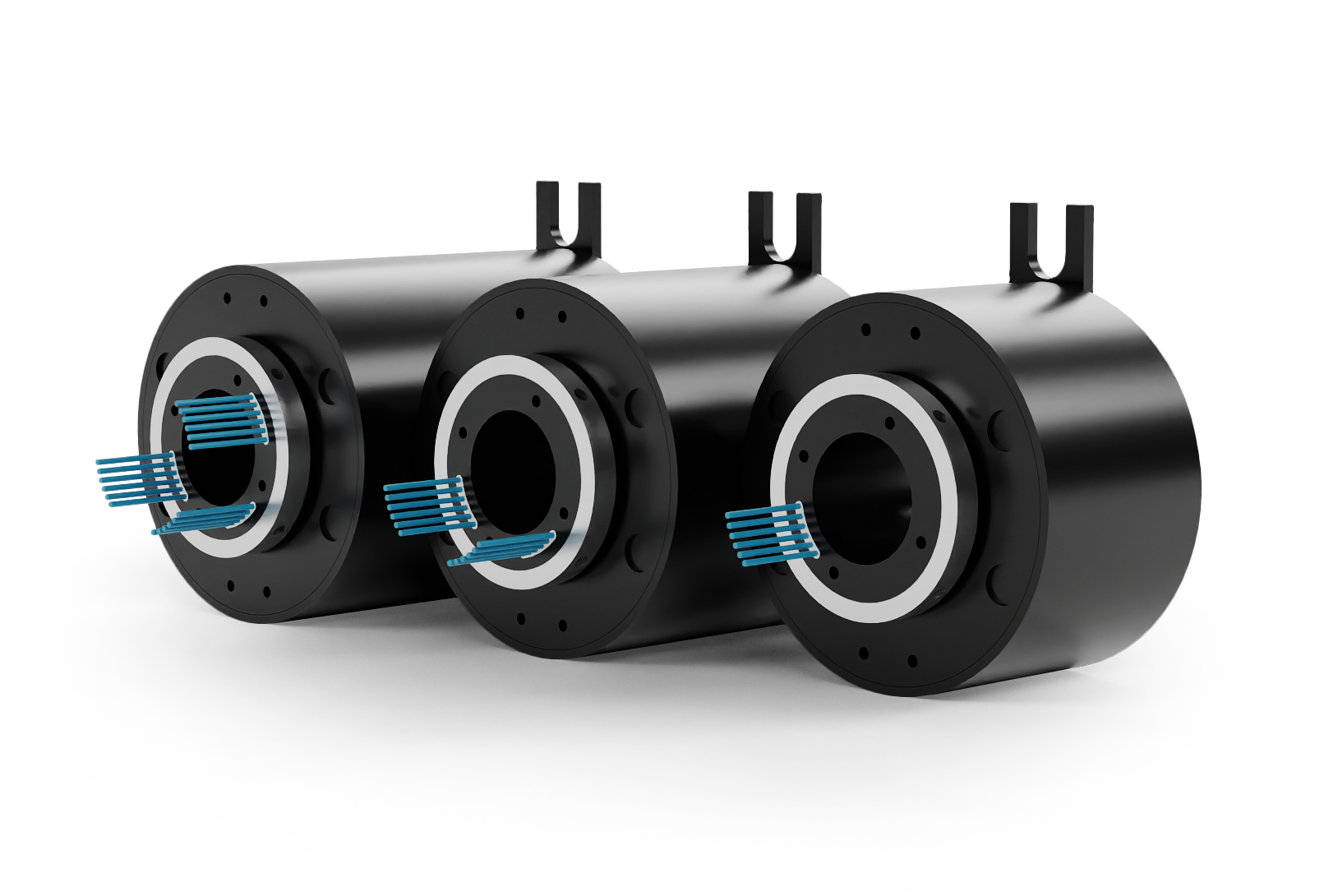

Pin Slip Ring Series

Our Pin Connection Slip Rings are precision-engineered to deliver seamless, high-current electrical connections, making them ideal replacements for mercury slip rings in the manufacturing sector. These slip rings feature gold-plated rings paired with gold alloy brushes to maximize performance, durability, and reliability in demanding industrial applications.

Modified Standard Solutions

Small Slip Rings for Winch Systems

We design through bore slip rings with integrated fiber optical rotary joints, tailored specifically for winch systems. These cutting-edge slip rings facilitate seamless electrical and optical transmission, ensuring continuous power, signal, and data flow between stationary and rotating parts.

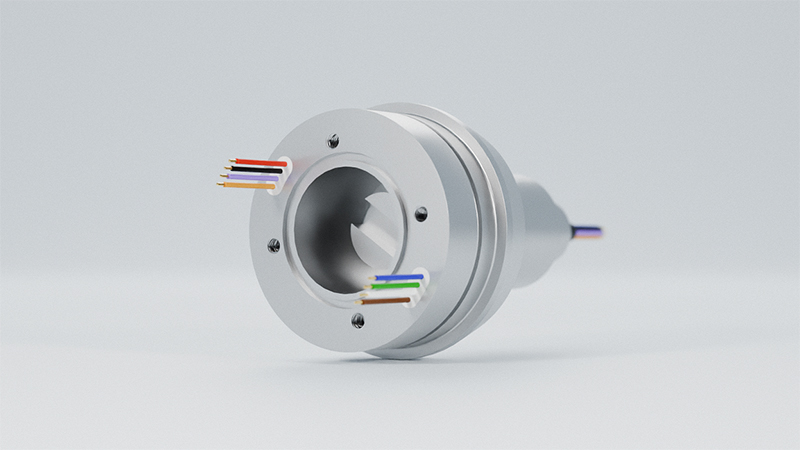

Encoder Fitted Slip Ring

We engineer compact slip rings with modified housings to accommodate small encoders for accurate position sensing. These advanced slip rings guarantee flawless electrical transmission, maintaining uninterrupted power and signal flow between stationary and rotating elements. The integration of the encoder enhances the precision and dependability of position sensing, making them ideal for applications requiring meticulous control.

Slip Rings for OEM Manufacturers

We develop modified standard hollow shaft slip rings for OEM manufacturers of packaging machines. These innovative slip rings ensure flawless electrical transmission, providing continuous power and signal flow between stationary and rotating components.

Our custom designs significantly improve the efficiency and reliability of packaging machines, allowing for precise control and uninterrupted operation.

Let's Talk

Share Your Project with Us – We’re Excited to Learn More!

Reach out to us, and we’ll try to respond within 24 hours. If you have not received an answer after 24 hours try calling us or e-mail us directly at info@penlink.se – sometimes form submissions get stuck in the spam filter.

For urgent matters, please call us right away at +46(0)84011010 or send us an e-mail.