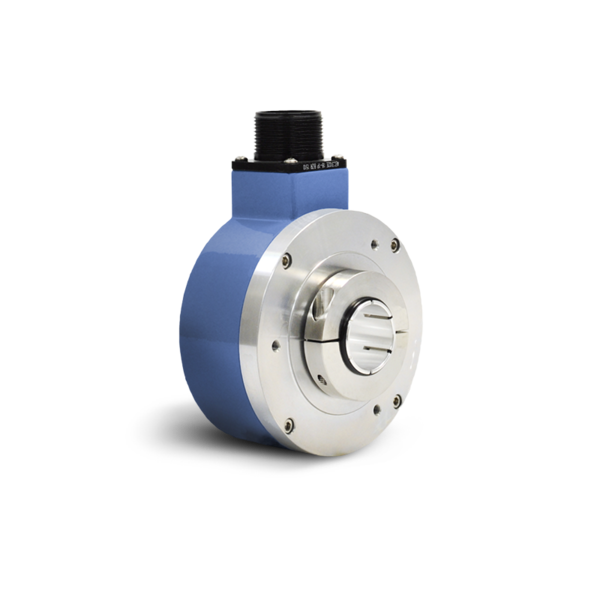

HS35A

Reliable Performance for Industrial Conditions

The HS35A magnetic encoders are engineered for versatility and reliability in industrial applications. With the ability to fit shafts ranging from 1/2″ to 1″ using a durable shaft insert, these encoders can be easily resized by replacing or removing the insert, providing fast customization for a variety of needs.

This feature allows quick responses from factories, distributors, and stockrooms, ensuring your encoder needs are met promptly. Additionally, the shaft insert and insulated bearings provide essential isolation from motor shaft currents, while also allowing for case grounding to meet NEC requirements.

Designed for durability, the HS35A encoders feature superior shaft seals and bearings that maintain their integrity even under extreme temperature cycling and liquid exposure. The seals are safeguarded by mechanical barriers to prevent flexing and failure, while synthetic lubricants in the bearings extend their lifespan.

Unlike many optical encoders that are vulnerable to vibration and shock, the HS35A uses robust, unbreakable disks and features a sensor-to-disk gap more than 8 times larger than the competition. These design enhancements make the HS35A encoder ideal for harsh industrial environments, ensuring reliable and continuous operation in demanding conditions.

- Fits shafts 1/2″ to 1″

- Simple Installation

- Up to 5000 PPR

- Unbreakable Optical Disk

- Wide-Gap Technology: Up to 8X larger gap between sensor and rotor

- Replaces Competitive Models without Rewiring

- Fits end of shaft and through shaft applications

- IP65/Nema 4, 13 Rating: Dust and Liquid Tight

- Superior Bearings and Seals

- -20°C to +100°C Operation *

- 2 Year No-Hassle Warranty