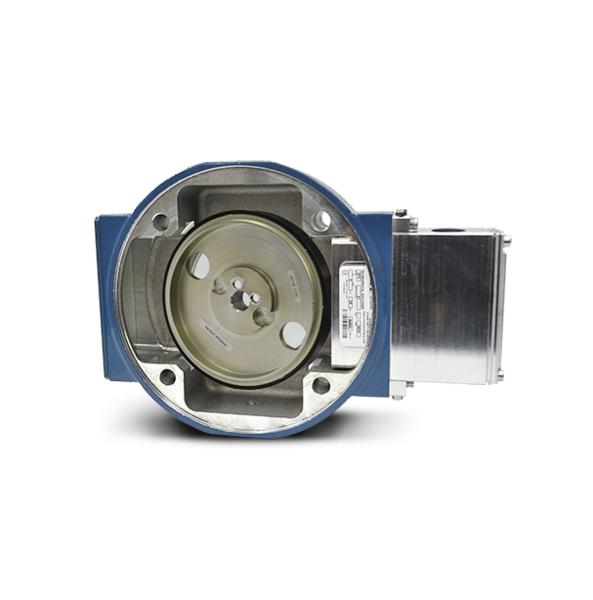

XPH8

Explosion-Proof, No-Bearing Reliability

The XPH8 SMARTSafe™ Magnetic Encoder is a groundbreaking solution for hazardous duty environments, being the world’s first explosion-proof encoder featuring removable electronics and no external barrier.

Certified to meet cULus, ATEX, AEx, and IECEx standards, the XPH8 excels in gas hazardous environments, providing unmatched reliability. Its no-bearing construction eliminates the common failure points found in traditional encoders, ensuring a longer operational lifespan even in the toughest conditions.

Designed for industries such as oil & gas, mining, and manufacturing, the XPH8 can be directly mounted on motors or equipment like top drives, draw works, and paint lines, providing continuous, reliable service.

For applications in ATEX/IECEx Zone 1 or 2 or cULus Class I, Division 1 or 2, Groups C & D, the XPH8 can be deployed without any additional barriers or isolators.

The encoder’s design includes advanced diagnostics, indicated by a green LED for good signal quality and an orange LED to signal any short circuit conditions, ensuring high uptime and efficient troubleshooting. With no encoder bearing failures or sealing issues, the XPH8 is ideal for environments subject to vibration, shock, liquids, dust, and dirt. Eliminate the leading cause of encoder failure by choosing the XPH8 hazardous duty encoder.

- No Barrier or Isolator Needed

- No Intrinsic Safety Ground Required

- Class I Div 1 Groups C, D Listed

- AEx Zone 1 Certified

- Zone 1 & 2 Certified

- Fits Shafts Up to 4.5″ [115mm]

- Fully Protected Against Shorts and Wiring Errors

- Adapters available to fit GEB20, 22, 28, GE 752 Motors

- Wide Sensor-Rotor Gap: No Shimming

- Up 100000 PPR

- -50°C to +85°C Operation

- 2 Year No-Hassle Warranty