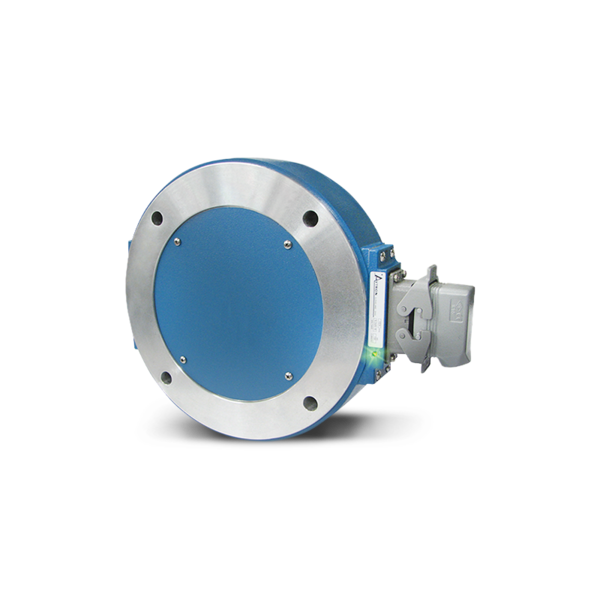

XR125

Heavy-Duty Performance for Large Shafts

The XR125 SMARTSafe™ Magnetic Encoder is a breakthrough solution for large shaft applications in hazardous environments. With ATEX/IECEx and cULus approvals, it is built for gas and dust applications, offering an exceptionally rugged, no-bearing design that eliminates a common failure point in industrial encoders.

Unlike traditional optical encoders with fragile bearings, the XR125 mounts directly on the main shaft, providing superior resistance to vibration, shock, liquids, and contaminants.

For Level 2 applications (ATEX/IECEx Zone 2 or UL Class I, Division 2), the XR125 can be used without barriers or isolators. For Level 1 (Zone 1 or Class I, Div 1), it pairs with the XRB1 or XRB2 isolator for intrinsically safe wiring.

SMARTSafe technology ensures protection against short circuits and wiring faults, making the XR125 ideal for demanding applications such as paint booths, draw works, and coil tubing rigs, keeping critical systems running 24/7.

- Fits NEMA 12.5″ Flanges

- Fits Shafts up to 7 7/8″ [200mm]

- ATEX/IECEx Rated for Zone 1, 2, 21 & 22 Applications

- Ideal for Oil and Gas Drilling

- No Bearings to Wear Out

- Fully Potted Electronics

- Up to 8192 PPR

- Self-Diagnostic LED and Alarm Output

- 3 Year No-Hassle Warranty

- cULus Class I Division 1 Groups A, B, C, D, Listed

- cULus Class I Zone 0 Group IIC

- cULus Class I Division 2 Groups A, B, C, D, Listed