Heavy Mill Duty Encoders

Heavy mill duty encoders are designed to withstand the harsh conditions of industrial environments, providing reliable and accurate feedback for various applications. These encoders are essential for ensuring the smooth operation of machinery in industries such as steel mills, pulp and paper, and cranes.

Our encoders are built to last, withstanding the toughest conditions in heavy-duty mill environments. With advanced technology and high-resolution capabilities, they provide accurate and reliable feedback. Additionally, we offer comprehensive support and service to help you select and maintain the right encoder for your needs.

- Rugged Construction: Built to endure extreme conditions, our heavy-duty mill encoders feature robust materials and construction that protect against shock, vibration, and contaminants.

- High Reliability: Engineered for maximum uptime, these encoders offer consistent performance even in the most demanding environments.

- Advanced Technology: Equipped with noise-resistant electronics and on-board diagnostics, our encoders ensure precise and reliable output.

Heavy Mill Duty Encoders

Advanced Magnetic Encoder Technology

At Penlink, we are proud to offer cutting-edge magnetic encoders from our trusted suppliers, renowned for their innovative technology and commitment to quality. These encoders utilize advanced magnetic sensing principles to provide accurate position and speed feedback in challenging environments.

Unlike traditional optical encoders, magnetic encoders are designed to withstand harsh conditions, including dust, moisture, and extreme temperatures, making them ideal for applications in industries such as offshore cranes, wind turbines, and mills. With their inherent durability, these encoders significantly reduce maintenance needs and enhance the lifespan of the systems in which they are integrated.

Our magnetic encoders are engineered for reliability and precision, employing features such as Wide-Gap technology that enhances performance by allowing greater distances between the sensor and the magnetic disk. This innovation significantly reduces the risk of sensor crashes and facilitates easier mounting, making installation straightforward.

Additionally, our encoders provide high resolution and excellent linearity, ensuring precise control and feedback for a wide range of motion applications. They are available in various configurations, including incremental and absolute models, to meet the diverse needs of our customers.

With their robust construction and superior signal output, our magnetic encoders deliver consistent performance, ensuring that your systems operate seamlessly and efficiently, even in the most demanding conditions.

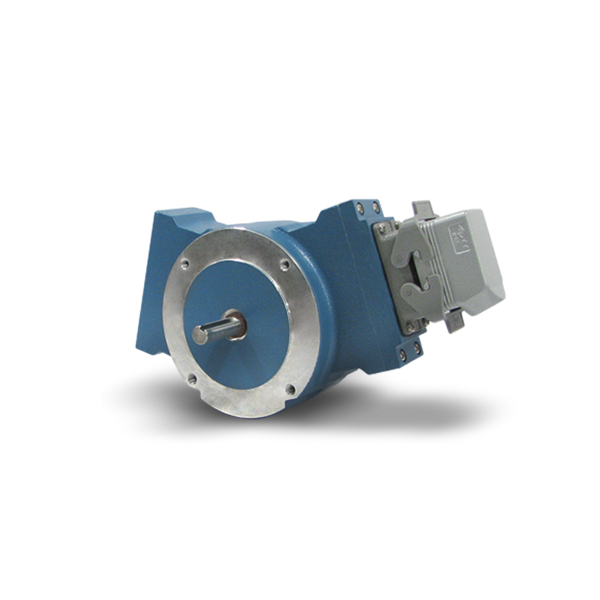

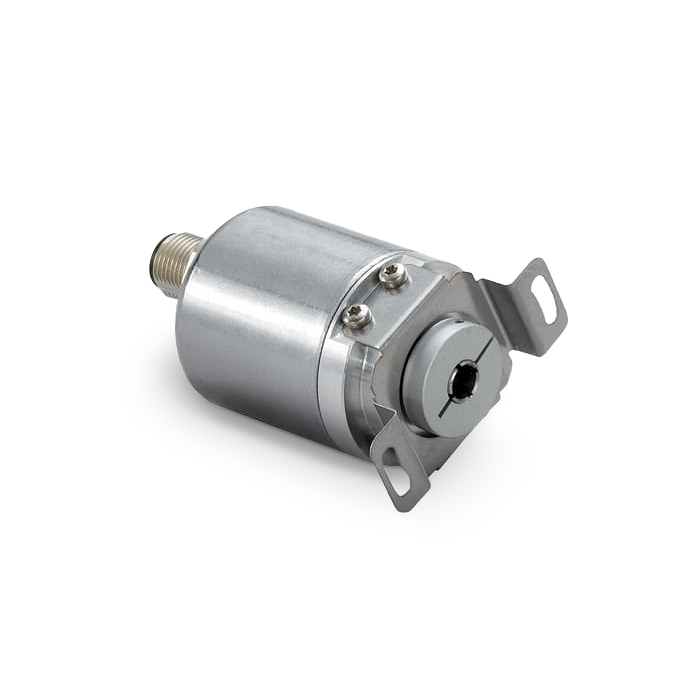

![Superior Durability for Industrial Applications

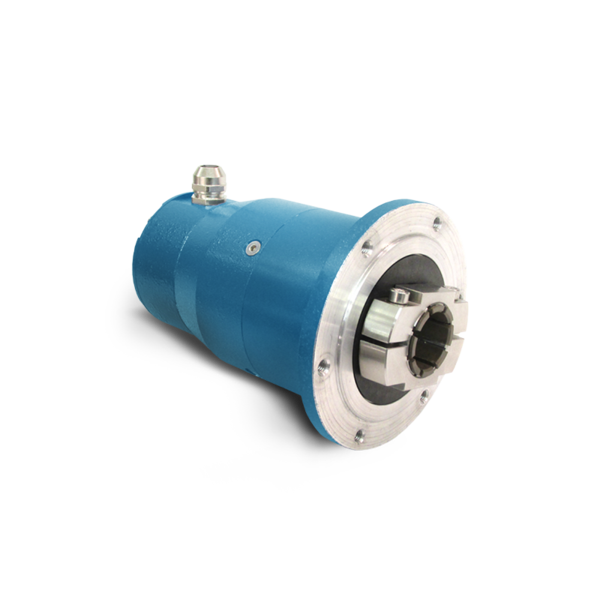

The HS6A Magnetic Encoder offers exceptional durability for industrial use, with a hollow shaft design that fits shafts from 0.3″ to 0.6″ [8-15mm].

Unlike ordinary optical encoders, the HS6A features robust seals and bearings that protect against contaminants and provide superior performance under harsh conditions.](https://penlink.se/wp-content/uploads/2024/11/csm_hs6a_5dd1a37174.png)