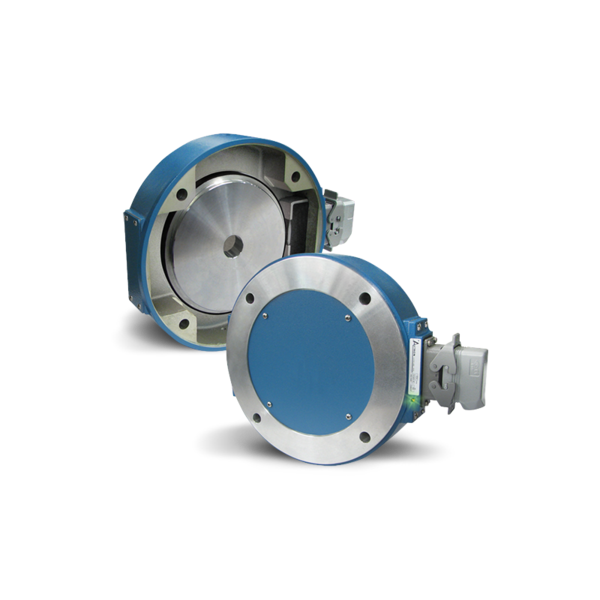

AV125

The Ultimate in Durability and Performance for Large Motor Applications

The AV125 SMARTach II™ magnetic encoder is specifically designed for large motor and brake applications, featuring a modular design that fits 12.5″ motor and NEMA brake flanges.

With the capacity to handle shafts up to 7 7/8″ [200mm], the AV125 facilitates motor-encoder-brake sandwich configurations and supports hollow shafts for water or air cooling systems to pass through. Its super-reliable performance and removable sensors make it the ideal solution for hard-to-access installations, eliminating downtime concerns in challenging configurations.

Engineered for durability, the AV125 boasts fully encapsulated electronics and eliminates moving wearing parts, offering a long-lasting solution that outperforms competitors. The sensors are positioned over 4 times farther from the rotor, reducing the risk of sensor-rotor grinding.

The AV125’s high-power outputs feature more than 50 times the capacity of standard encoders, with protection against short circuits, reverse voltage, and surges.

Additionally, the encoder’s digital self-tuning sensors and advanced diagnostics ensure optimal performance, alerting operators to potential issues before failure occurs, keeping your equipment running smoothly. Forget unreliable optical encoders and choose the AV125 for superior durability and efficiency.

- Heavy Mill Duty

- Up to 7.88″ [200mm] Shafts

- Up to 8192 PPR

- Removable Sensors

- Wide-Gap Technology, No Air Gap Adjustment Required

- Mounts Securely to Motor

- Outputs Fully Short Circuit Protected

- Self-Diagnostic LED & Alarm Output

- Sealed Electronics

- -40°C to +100°C Operation

- 3 Year No-Hassle Warranty

- Excellent for Brake Applications