Denali Series

Best-in-class Efficiency With Optimal Performance

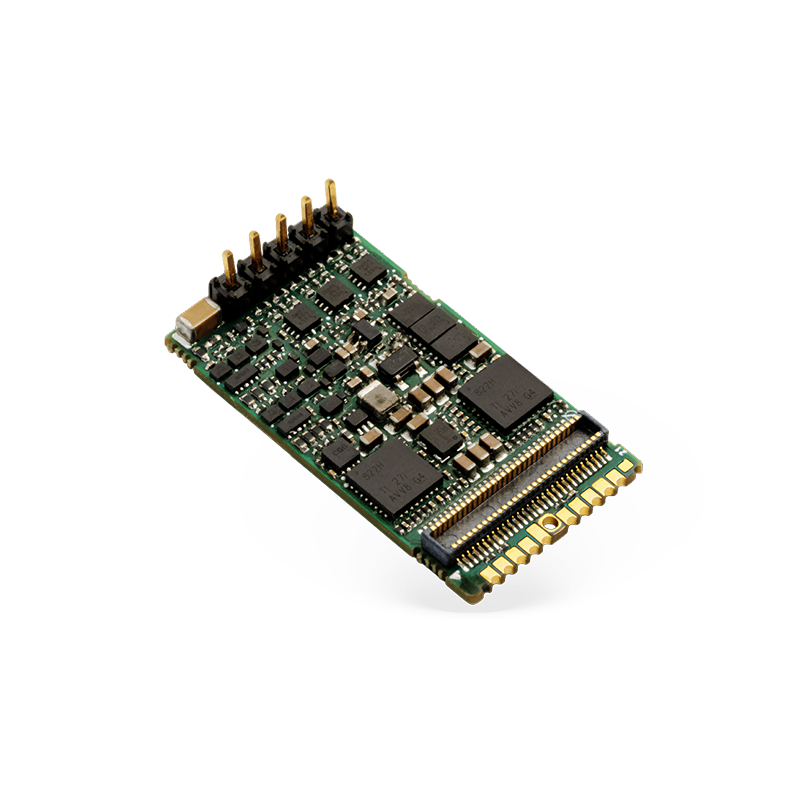

The Denali Series features an ultra-flat, low-profile design for easy integration across multiple applications. Lightweight, Denali NET weighs just 4 g and Denali XCR 14 g.

Denali offers ultra-fast servo loops with a 50 kHz current loop and 25 kHz position and velocity loops, ensuring top motor performance. The series includes plug-in versions for PCB integration (Denali NET) and ready-to-use versions with cable connections (Denali XCR).

For high-speed communication, Denali CORE uses an SPI bus with network update rates up to 30 kHz, enhancing cost-efficiency in multi-axis architectures. Denali also supports dual loop position control for superior accuracy, precision, and stability, accommodating both daisy-chained and decoupled absolute encoder architectures.

See the specification tab for more technical details!

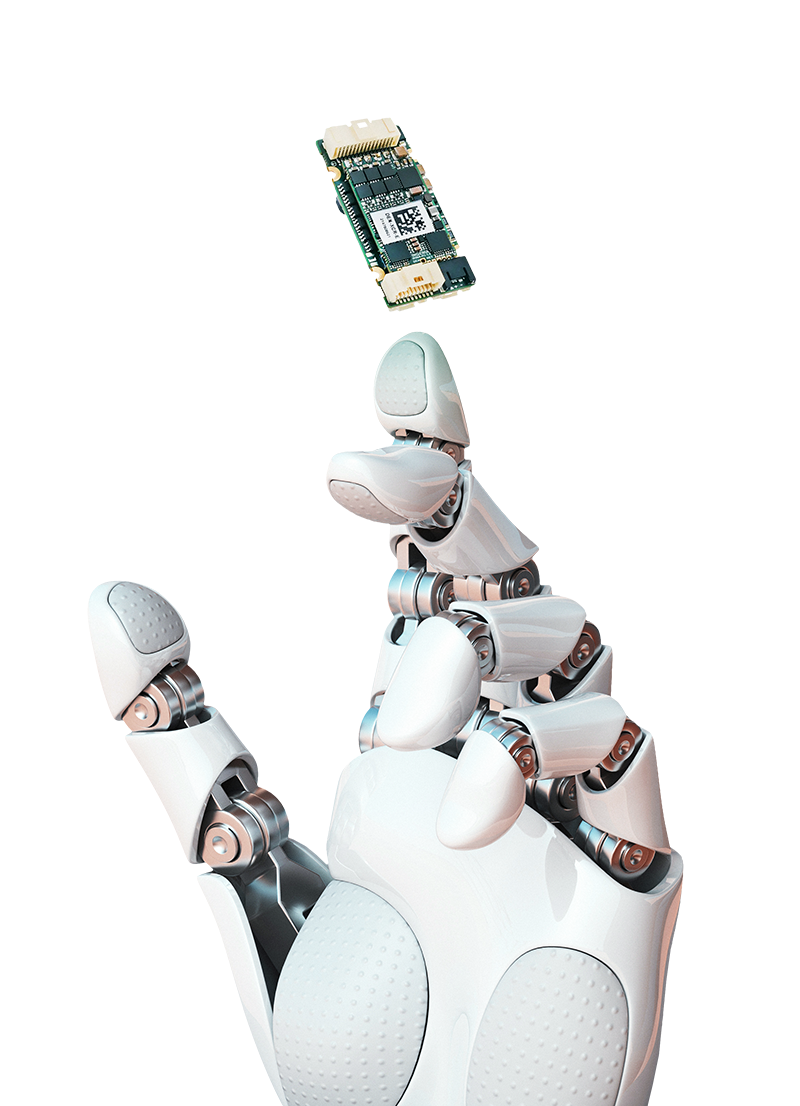

The World's Smallest Servo Drive

Denali Series Features

Miniature Servo Drive

The Denali footprint has been minimized to an extremely low profile, resulting in a lightweight design.

Super Low Latency

Efficiency up to 99% due to state-of-the-art power stage and standby power consumption down to 1.12 W, the Denali Series sets a new standard for servo drive power management.

Low EMI

Ready-to-use Denali XCR allows quick system start-up. The pluggable module, Denali NET, allows easy integration into carrier boards.

EtherCAT/ CANopen

Denali has been designed to meet industrial functional safety standards to ensure continuous operation safety. STO inputs are integrated, rated to SIL-3 PLe.

Superior Power Management

Fast current and servo loops, with PWM frequencies up to 200 kHz delivering best-in-class performance.

Dual Loop Support

Denali supports dual loop position control to achieve accuracy, precision and stability. Both daisy-chained or decoupled absolute encoder architectures are supported.