Everest S Series

Smaller, With All Its Power And Zero Compromises

With a slimmer profile, Everest S is now able to fit into any application with confined space, delivering the same performance and best-in-class efficiency. Plug it in or wire it, Everest S fits in virtually any possible application.

EtherCAT and CANopen versions are available with a bus latency down to 1 cycle, outpacing any of its market competitors. High-speed SPI bus communication is also available for optimized EtherCAT/CANopen multi-axis architectures.

Everest S is able to provide a current loop running at 50 kHz and a velocity loop at 25 kHz, guaranteeing optimal performance for your motors. Combined with a 16-bit differential current sensor and 3 configurable ranges, Everest S delivers flawless resolution.

- Surgical Robots

- Exoskeletons

- Pan Tilt Gimbals

- Collaborative Robots

- Legged Robots

- AMRs

Boost Your Performance

Everest S Series Features

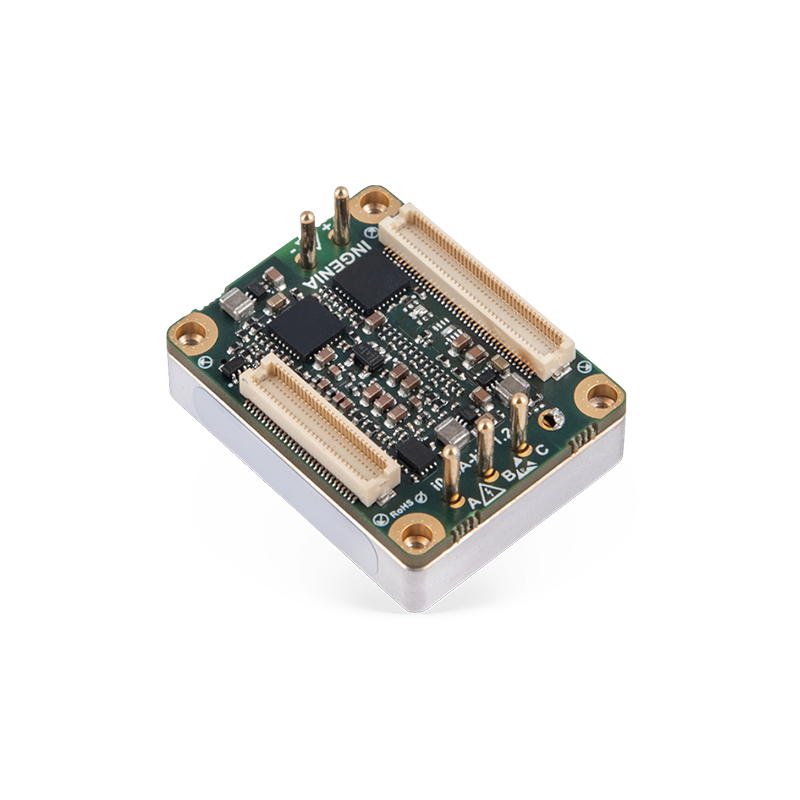

Ultra-Compact Design

Everest S footprint has been minimized to an extremely low profile, resulting in a lightweight design.

Superior Power Management

Fast current and servo loops, with PWM frequencies up to 100 kHz delivering best-in-class performance.

Multiple Integration Options

Ready-to-use Everest S XCR allows quick system start-up. The pluggable module, Everest S NET, allow easy integration into carrier boards.

Safety First

Everest S has been designed to meet industrial functional safety standards to ensure continuous operation safety. STO inputs are integrated, rated to SIL-3 PLe.

Best-in-class Servo Performance

Efficiency up to 99% due to state-of-the-art power stage and standby power consumption down to 1.12 W, Everest S sets a new standard for servo drive power management.

Demanding Multi-axis Applications

Everest S supports EtherCAT with a bus latency down to 1 cycle. Support for CANopen communication is available.