Everest Series

Introducing the Everest Servo Drive Family

Whether you’re designing multi-axis systems, distributed control applications, or space-constrained robotics, Everest servo drives deliver unparalleled performance and adaptability across a range of demanding applications.

All models offer unmatched efficiency with rates up to 99%, ensuring minimal heat dissipation even under heavy loads.

Experience industry-leading motor performance with advanced current, position, and velocity control loops. Engineered to fit even the tightest spaces, Everest drives set new standards in power density and functionality.

Seamlessly integrate into diverse system architectures with options for SPI, CANopen, and EtherCAT communications. Additionally, Everest models come with safety certifications like STO SIL3 PLe, providing maximum reliability in critical applications.

World Class Components

Everest Series Features

Smallest Servo Drive

Everest is the smallest servo drive in the world for it’s power range and functionality. It has been designed with robotics developers in mind where space is at a premium.

99% Efficiency

With an efficiency up to 99% due to its state-of-the-art power stage the Everest sets new standards for low heat dissipation in servo drives.

Current Range

Everest includes 16 bit differential current sensing with 4 configurable ranges so that you can get the best resolution for each application.

Plug-in module

Integrate Everest NET into your own PCB design to get the highest performance from your robotic joint. Or easily integrate the XCR into your robotic joint or motor – just wire and configure and you’ll be running!

Guided Configuration

MotionLab Configuration Software comes for free with every Everest servo drive. It lets you configure and tune your drive to get your application running.

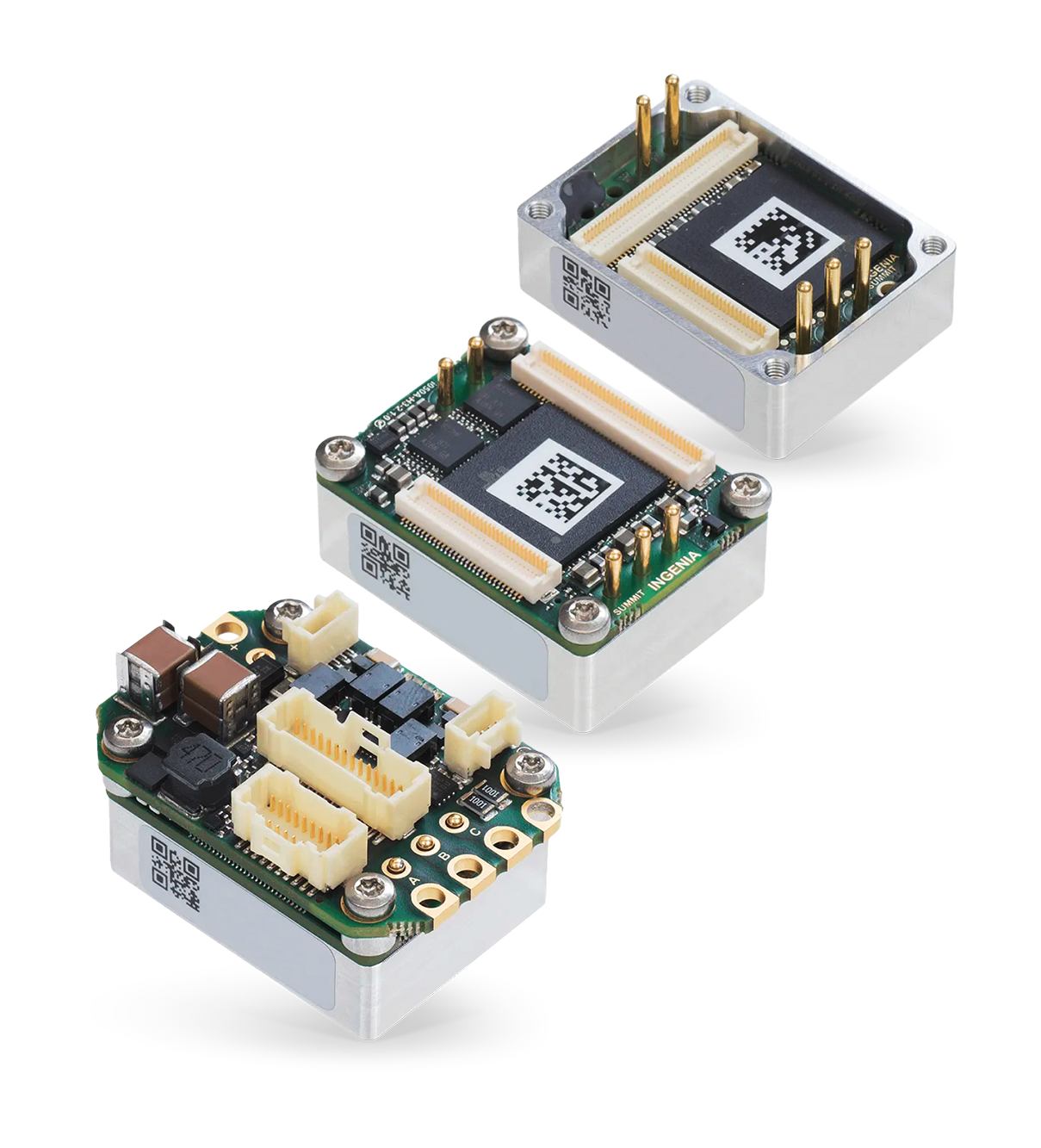

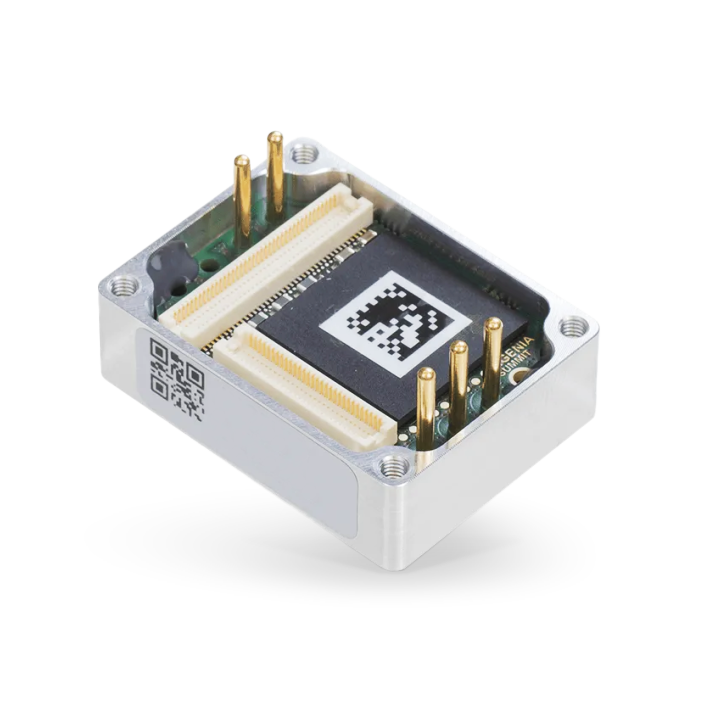

Everest CORE

Everest CORE offers developers a module with maximum motor control capabilities and flexible communication management. It uses an ultra-fast, safe SPI bus for multi-axis applications. Everest includes 16-bit differential current sensing with 4 configurable ranges for optimal resolution. With up to 99% efficiency and low heat dissipation, it sets new standards for servo drives. The current loop runs at 75 kHz, and the position and velocity loops at 25 kHz, providing top performance.

Controlled through an SPI bus with command updates up to 30 kHz, it enhances cost-efficiency for embedding multiple axes into a single PCB while maintaining high performance and communication speeds. The Everest CORE also reduces heat with a low standby power consumption of only 1.5 W.

| Specification | |

| Continuous Current | 45 A |

| Peak Current | 60 A (3s) |

| Efficiency | 98 % |

| Functional Safety | STO SIL3 Ple (TÜV certified) |

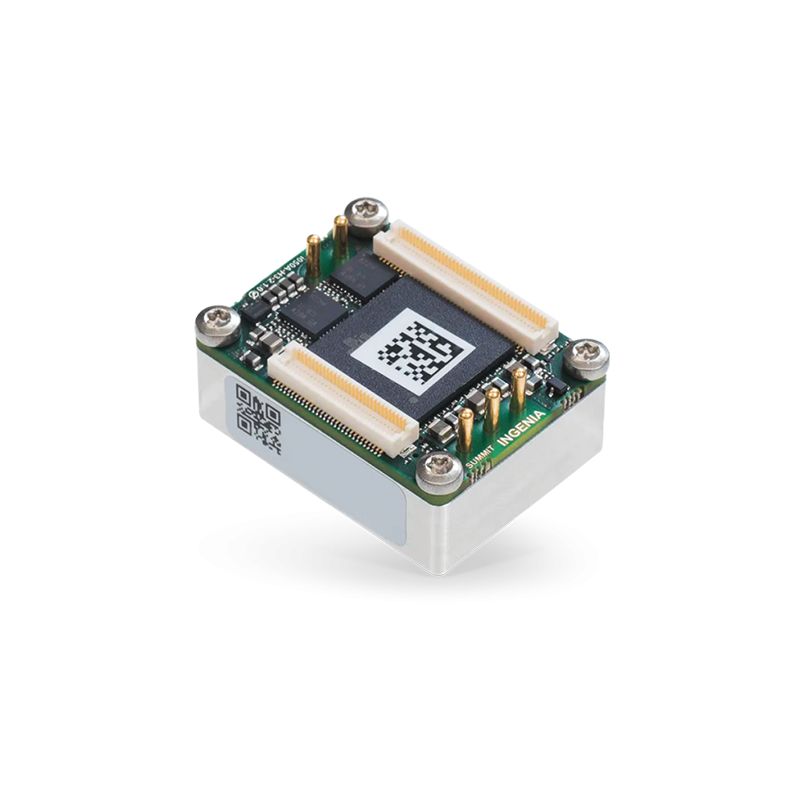

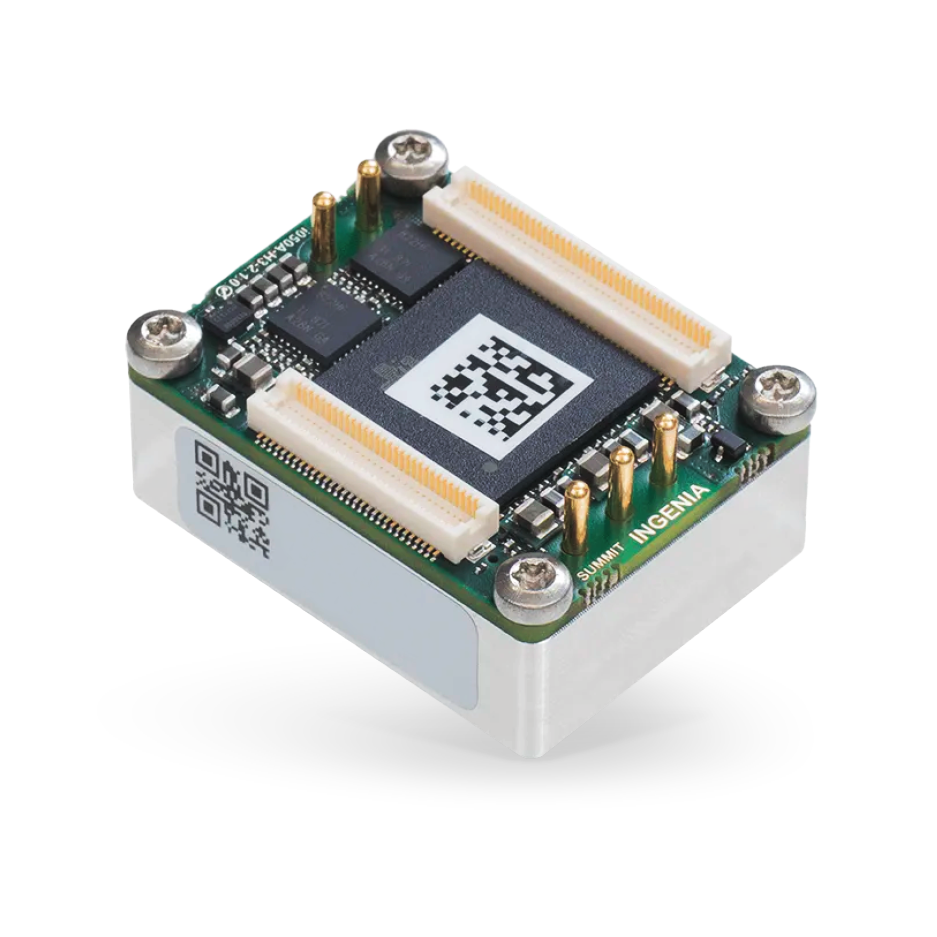

Everest NET

Everest NET is based on the Everest CORE technology and includes CANopen and EtherCAT communications. Everest NET is the ideal solutions for distributed control applications that require specific form factors and additional circuitry. The Everest NET can be easily integrated into your own PCB design with its plug-in design.

The Everest NET supports both CANopen or EtherCAT communications which can be set through the configuration software interface. Everest NET architecture allows for an EtherCAT bus latency of 2 cycles which is 125% faster than any comparable servo drive. Connect the Everest NET directly to your PCB without soldering if your continuous current is below ten amperes. Integrate Everest NET into your own PCB design to get the highest performance from your robotic joint. The Everest NET is STO SIL3 PLe TÜV certified.

| Specification | |

| Continuous Current | 45 A |

| Peak Current | 60 A (3s) |

| Efficiency | 98 % |

| Functional Safety | STO SIL3 Ple (TÜV certified) |

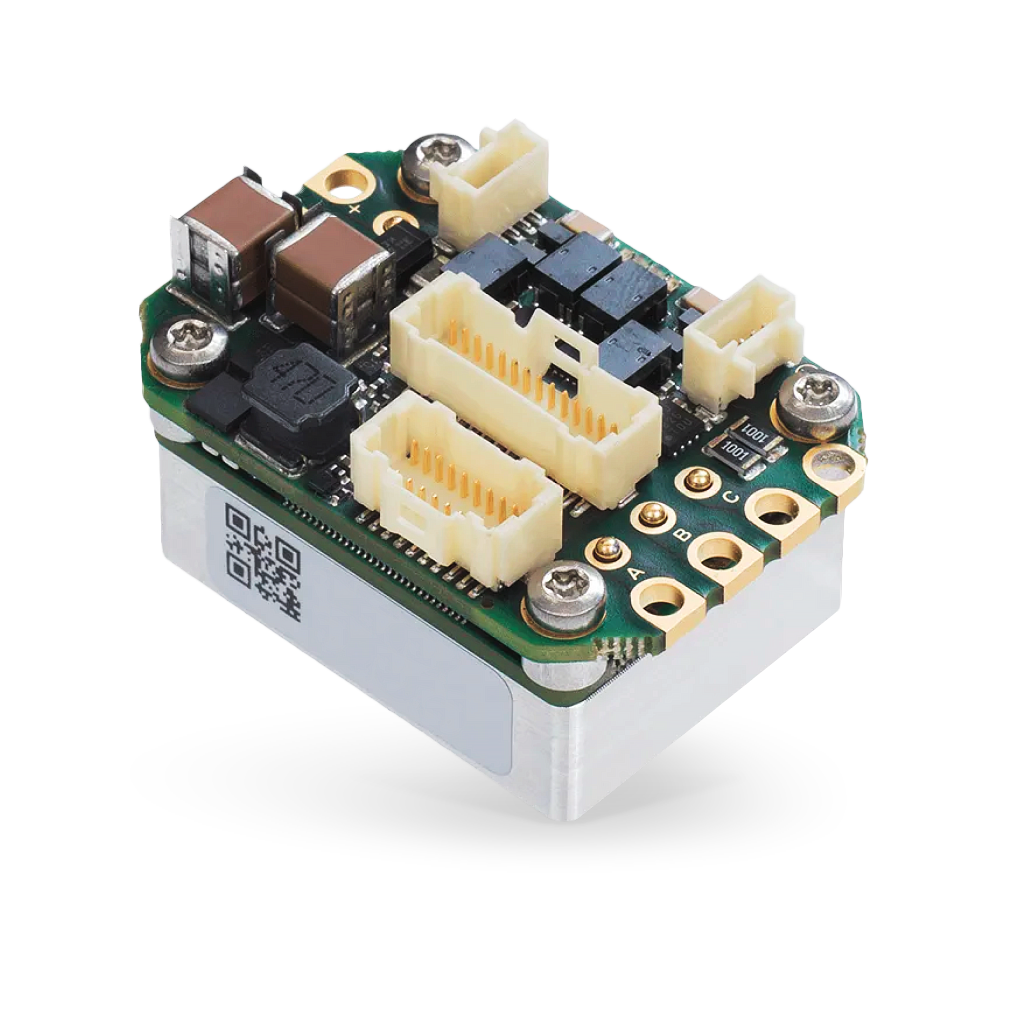

Everest XCR

Everest XCR is based on the Everest NET technology and includes CANopen and EtherCAT communications. Everest XCR comes with connectors to facilitate its integration into your system. The drive features the most advanced transistor technology in the world and delivers the highest power density and efficiency while keeping negligible EMI.

Everest XCR is the smallest servo drive in the world for it’s power range and functionality. It has been designed with robotics developers in mind where space is at a premium. Just connect your motor, configure your drive with MotionLab and get your robot or motor running.

Easily integrate Everest XCR into your robotic joint or motor. You will just have to wire and configure your drive to get running. MotionLab Configuration Software comes for free with every Everest servo drive. It lets you configure and tune your drive to get your application running. Connect two BiSS-C encoders on daisy chain to Everest and reduce the wiring on your application.

| Specification | |

| Continuous Current | 45 A |

| Peak Current | 60 A (3s) |

| Efficiency | 98 % |

| Functional Safety | STO SIL3 Ple (TÜV certified) |