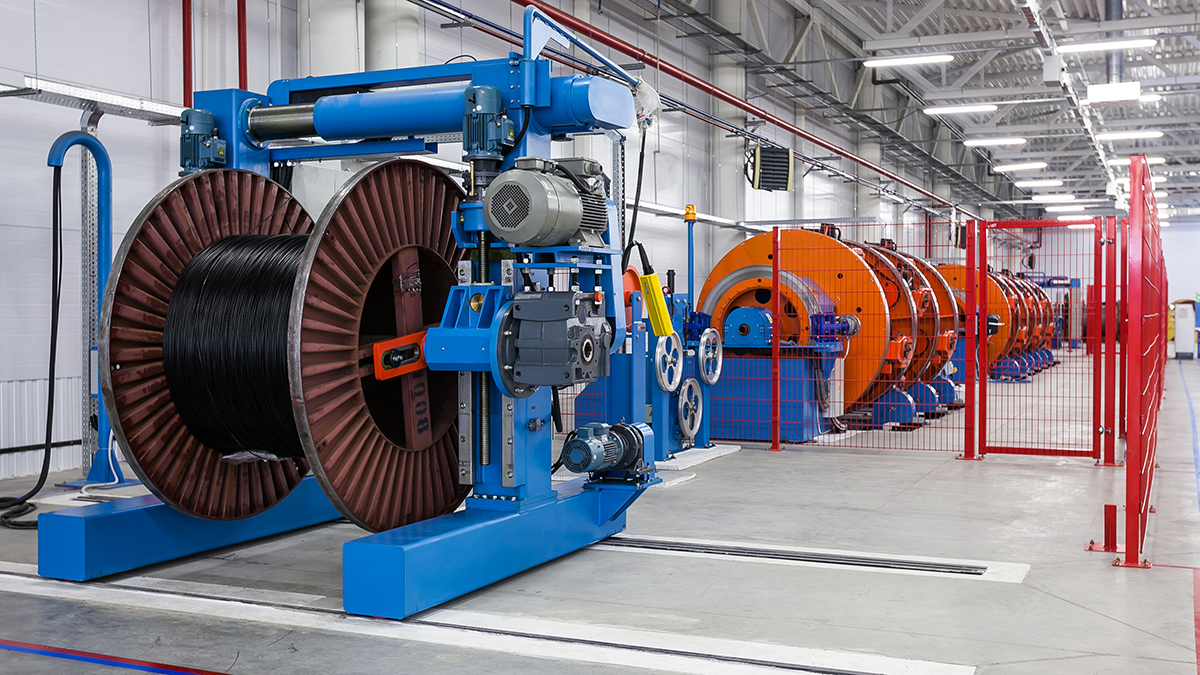

Cable Manufacture Slip Ring

Designed for Though Jobs

This slip ring integrates seamlessly into Vertical Lay-up Machines capable of holding interchangeable baskets with payload capacities of 250, 500, or 750 tons. Its performance ensures reliable operation in heavy-duty applications where power and data must be transferred smoothly.

At Penlink, we specialize in modular slip ring designs that combine precision, reliability, and efficiency. Our slip rings are engineered to meet the demands of modern manufacturing processes, ensuring consistent performance over time.

Contact us to learn more about how this slip ring can enhance your manufacturing capabilities.

Relevant Documents

Versatile Solutions for Similar Applications

This type of slip ring is not limited to Vertical Lay-up Machines; its robust design makes it an excellent choice for a variety of similar high-demand applications, such as cable carousels, large-scale rotating platforms, and industrial machinery requiring both power and data transfer. The slip ring’s ability to handle high currents (up to 800A) and simultaneous data communication over Profinet and Ethernet ensures reliability in complex systems.

One of the key challenges in this industry is maintaining consistent performance in harsh environments where dust, humidity, and temperature fluctuations are common. Our design addresses these issues with an IP54 rating for protection against ingress and a stainless steel housing, ensuring durability and longevity. Additionally, the optimized rotational speed of up to 10 rpm minimizes wear while providing smooth operation for large payloads.

By combining power and data transfer in a compact, reliable design, Penlink’s slip rings simplify system integration, reduce maintenance needs, and enhance overall operational efficiency—delivering a dependable solution for demanding industrial applications.