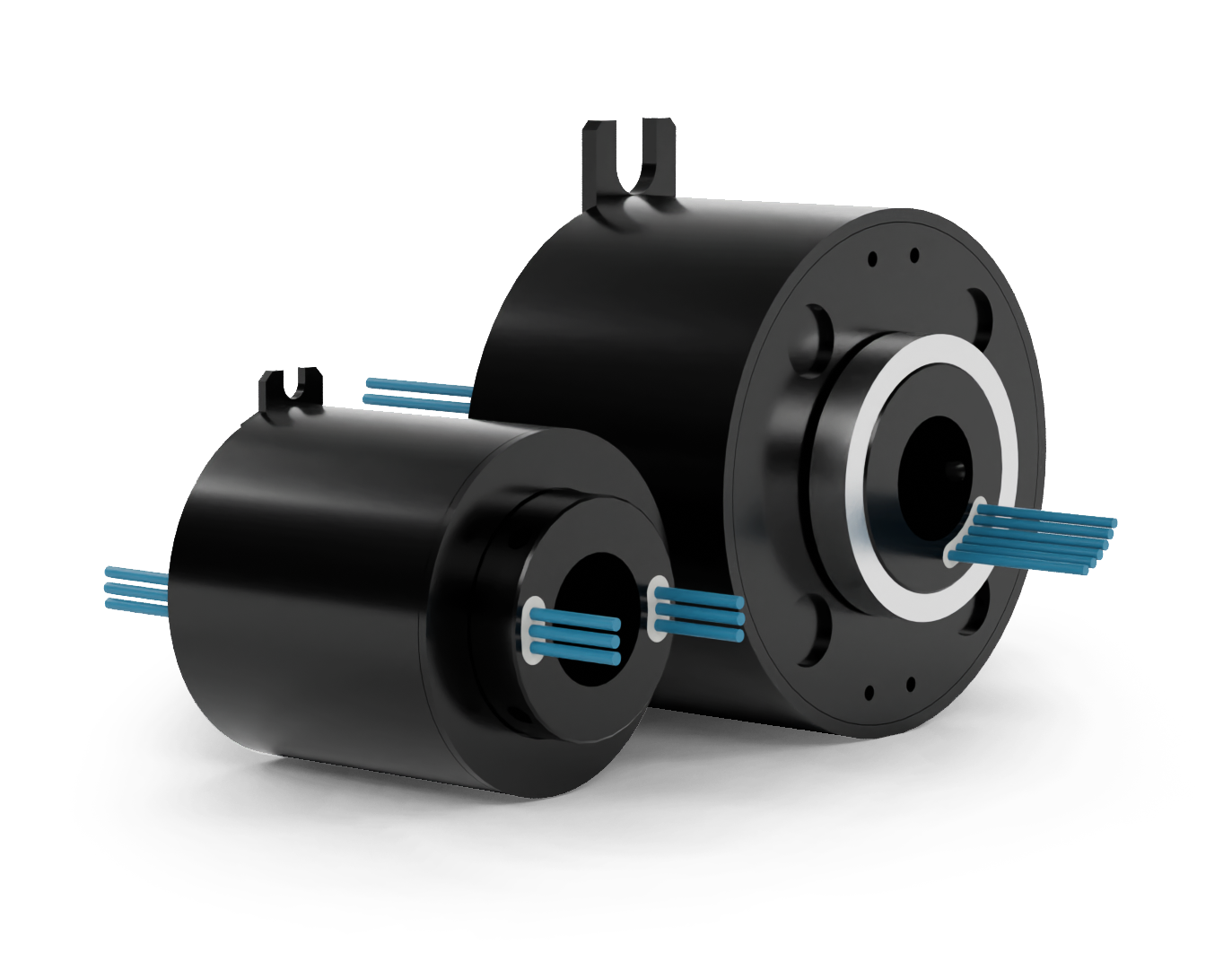

Hollow Shaft Slip Rings

Seamless Signal & Data Transmission

Experience seamless signal and data transmission even during full 360° rotation, thanks to our cutting-edge fiber brush technology. Our slip rings require no maintenance or lubricating oil, ensuring hassle-free operation. With low torque and smooth rotation, they deliver reliable performance.

Electrical noise is kept below 0.01 Ω for pristine signal quality. Featuring multiple contact points in each circuit, they operate with minimal contact pressure, resulting in low noise and wear.

Moreover, we offer extensive customization options for flange, cables, housing, IP-rating, transmission, circuits, and connectors with our standard selection of slip rings. If your needs extend beyond standard modifications, we’re prepared to tailor our slip rings precisely to your application requirements.

Typical Applications

- Industrial machinery, rotary index table

- Heavy equipment turrets, cable reels, test equipment

- Packaging machines, palletizing machines, magnetic clutch, process equipment

- Rotary sensors, emergency lighting, robotics

- Exhibit/display equipment, medical equipment

- 17 Control system of hotel revolving door

Small Hollow Shaft Slip Rings

PSH-X12-35 | PSH-X12-54

The rotary electrical slip ring features four lead exits evenly distributed on the rotor side and two on the stator side, facilitating smooth power transmission. With a versatile voltage rating of 240VAC/VDC and a rated current of 5A per ring, it ensures reliable performance.

The leads are AWG22 silver-plated and PTFE insulated, with a standard length of 500mm, offering excellent insulation resistance of ≥500MΩ/500VDC and dielectric strength of 500VAC/50Hz for 60 seconds. Electrical noise is minimized to ≤10mΩ. Its protection level stands at IP51, ensuring adequate safeguarding in various environments.

PSH-X12 Base Configuration

| Model | Length (mm) | Max. Circuits | Ampere | Max. Modified Circuits | Inner Diameter (mm) | Outer Diameter (mm) |

| PSH-X12-35 | 29,5-40 | 12 | 2A/5A | Contact us for more info | ⌀12 | ⌀35 |

| PSH-X12-54 | 33,4-75,2 | 24 | 2A/5A | Contact us for more info | ⌀12 | ⌀54 |

Standard Hollow Shaft Slip Rings

PSH-X25 to PSH-X100

Our PSH-X25, PSH-X38, PSH-X50, PSH-X60 PSH-X70, PSH-X80, PSH-X90, and PSH-X100 models, designed for seamless power and signal transmission, come standardized with technical and mechanical specifications, ensuring compatibility across various applications. They deliver reliable performance with a rated voltage of 380VAC for power and 240VAC/VDC for signal, making them suitable for diverse applications.

The slip rings boast superior insulation resistance, exceeding ≥1000MΩ/500VDC for power and ≥500MΩ/500VDC for signal, ensuring robust electrical insulation. Constructed with insulated PVC or PE for power and AWG22 silver-plated wires with PTFE insulation for signal, they guarantee efficient current flow and minimal signal interference.

Our slip rings offer exceptional dielectric strength of 500VAC@50Hz for 60 seconds, ensuring durability and safety. With a rated speed of 250/500rpm, they maintain optimal performance even in demanding conditions, operating within a wide temperature range of -20°C to +80°C and humidity levels of 60%RH or higher.

Constructed with precious metal contacts and an engineering plastic housing, our slip rings minimize torque to 0.1N·M for the -6 version, with an additional 0.03N·M torque increase for every six rings added. Additionally, they offer a standard protection level of IP51, with optional upgrades to IP54 or IP65 for enhanced environmental protection. These slip rings ensure versatility and flexibility in design and installation.

PSH-X Base Configuration

| Model | Length (mm) | Max. Circuits | Ampere | Max. Modified Circuits | Inner Diameter (mm) | Outer Diameter (mm) |

| PSH-X25-78 | 55-127 | 48 | 2A/10A/15A | 96 | ⌀25 | ⌀78 |

| PSH-X38-99 | 54,1-126,1 | 48 | 2A/10A/15A | 96 | ⌀38 | ⌀99 |

| PSH-X50-120 | 69,5-219,5 | 72 | 5A/10A/15A/20A | 156 | ⌀50 | ⌀120 |

| PSH-X60-135 | 77,5-287,5 | 96 | 5A/10A/15A/20A | 216 | ⌀60 | ⌀135 |

| PSH-X70-155 | 80,8-290,8 | 96 | 5A/10A/15A/20A | 216 | ⌀70 | ⌀155 |

| PSH-X80-180 | 88,5-298,5 | 96 | 5A/10A/15A/20A | 216 | ⌀80 | ⌀180 |

| PSH-X90-190 | 88,5-298,5 | 96 | 5A/10A/15A/20A | 216 | ⌀90 | ⌀190 |

| PSH-X100-203 | 93,5-314 | 80 | 5A/10A/15A/20A | 216 | ⌀100 | ⌀203 |