Introducing the SV850, the world’s first safety-rated no-bearing encoder for SIL 2 applications. Unlike optical encoders that often fail due to dust or water contamination, the SV850’s advanced magnetic technology sees through contamination. Its fully sealed circuit design ensures your machine keeps running smoothly, even in harsh mill environments. Experience superior magnetic performance and moisture resistance with the SV850!

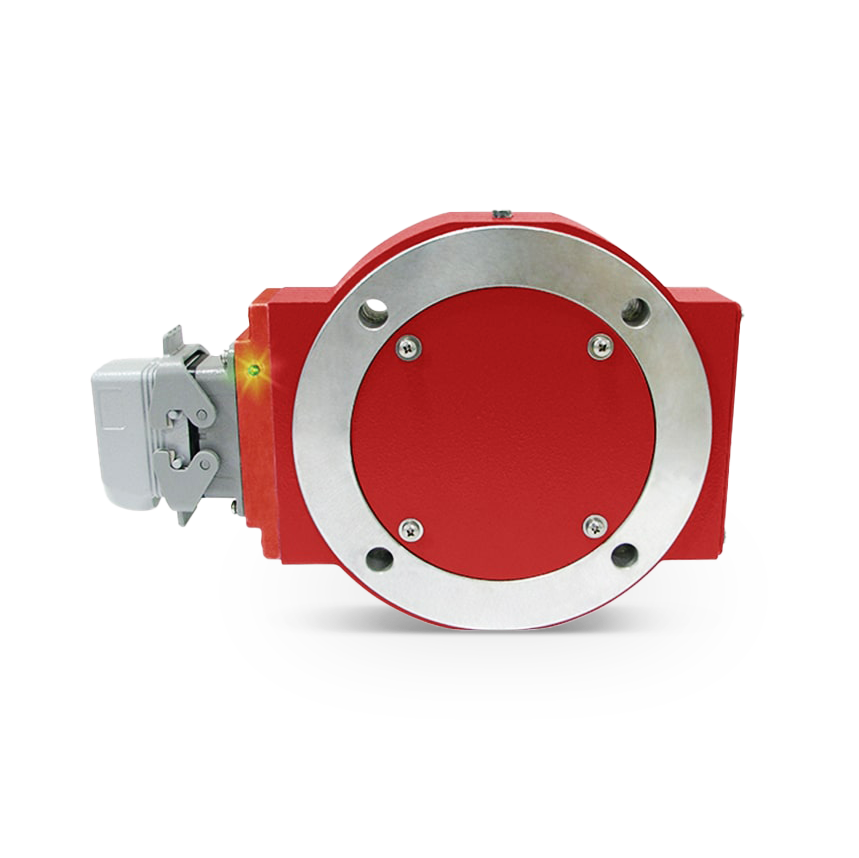

The SV850 SAFETach™ III safety modular magnetic encoders are designed to fit standard 8.5″ FC-Face motors. Engineered to eliminate encoder failures, the SV850 features fully encapsulated electronics with no moving parts, ensuring long-lasting durability.

Miswiring an encoder is a common issue, but it shouldn’t cost you time or money. The SV850 detects wiring errors and short circuits that cause over-temperature situations, indicated by an orange LED. It offers full output short circuit and reverse voltage protection, plus surge protection. The SV850 SAFETach III sensors digitally self-tune the outputs, eliminating drive trips caused by poor encoder signals. The universal 5-24V design supports longer cables and is safeguarded against wiring errors and surges.

At power-up, a green LED confirms proper installation and signal reading. If the SV5 sensor encounters inconsistent signals, the LED turns red and activates an optional remote alarm contact, while the encoder continues to operate, allowing you to schedule maintenance. Wiring errors and short circuits causing over-temperature conditions are indicated by an orange LED.

Why settle for a competitor’s “safety” encoder that fails due to optical issues? Choose the SV850 for unmatched safety and reliability.