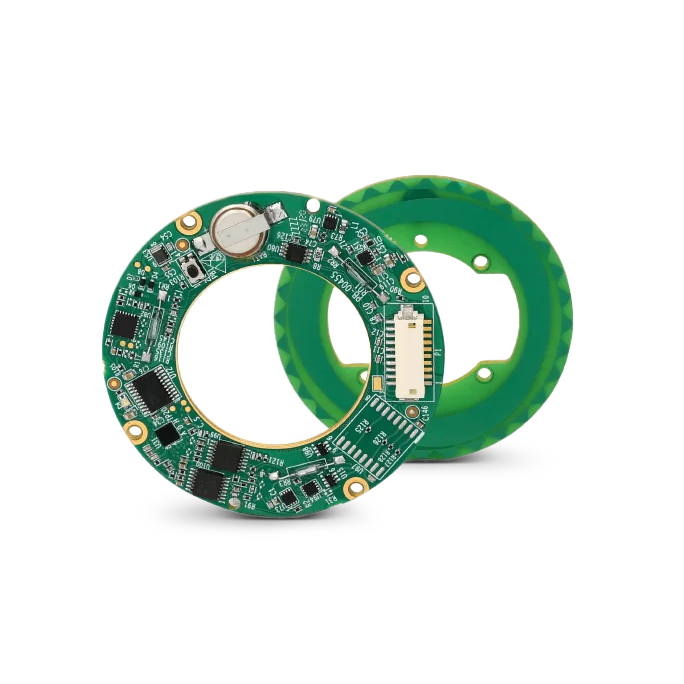

VLM Series

Compact, durable, and precise – the VLM Series Encoders deliver accurate motion control for industrial and automation applications

The VLM Series Encoders are engineered for high-precision motion feedback in demanding environments. Designed with robust materials and advanced sensing technology, these encoders provide accurate position tracking, ensuring smooth and efficient performance across various industries. Whether you need reliability in harsh conditions or compact integration into your system, the VLM Series offers a solution that meets your needs.

The VLM Series Encoders combine precision, durability, and flexibility, making them ideal for industries that demand accurate and consistent performance. With a design focused on long-lasting reliability and seamless integration, these encoders help maximize efficiency while reducing maintenance and downtime. Whether you are upgrading existing systems or designing new applications, VLM encoders provide the accuracy and dependability you can trust.

- High Resolution & Accuracy: Provides precise position feedback for optimized performance.

- Rugged & Durable Design: Built to withstand harsh industrial environments.

- Compact & Lightweight: Easy integration into space-constrained applications.

- Multiple Output Options: Available in incremental and absolute configurations.

- Extended Temperature Range: Ensures reliable operation in extreme conditions.

- Low Power Consumption: Optimized for energy-efficient systems.

| Model | VLM-60 |

| OD | 60 mm |

| ID | 25 mm |

| Height | 8 mm |

| Weight | 15 gr |

| Resolution | 17 bit |

| Accuracy | ±0.010° |