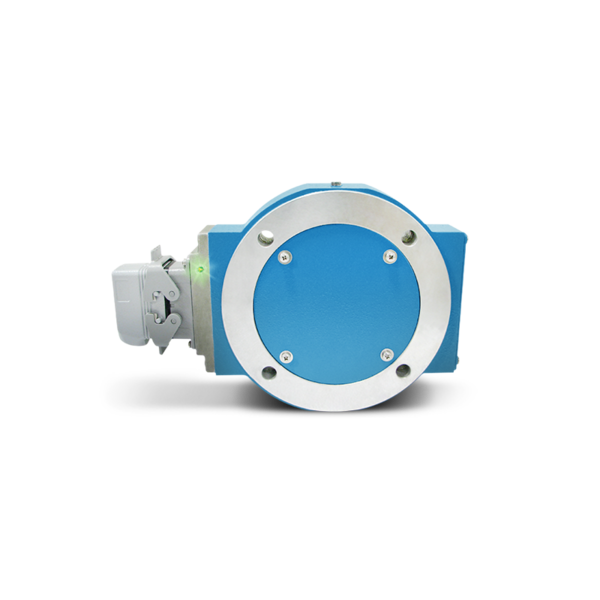

XR850

The Pinnacle of Hazardous Duty Reliability

The XR850 SMARTSafe™ 8.5″ Magnetic Encoder sets a new standard in hazardous duty rotary encoders. With modular, no-bearing construction and certifications for ATEX, IECEx, and cULus environments, it delivers unmatched durability and performance.

Designed for UL gas and ATEX/IECEx gas and dust applications, the XR850 eliminates the need for barriers, isolators, or explosion-proof glands in Level 2 environments. This rugged encoder withstands vibration, shock, liquids, dust, and dirt, making it ideal for demanding industries such as paint booths, coil tubing rigs, and draw works.

For Level 1 applications, the XR850 integrates seamlessly with XRB1 or XRB2 isolators, enabling intrinsically safe wiring in hazardous environments. Unlike traditional optical encoders prone to weak bearings and faults, the XR850 mounts directly onto your main application shaft, ensuring long-term reliability.

Equipped with SMARTSafe™ technology, it provides protection against short circuits and wiring faults, ensuring 24/7 operation. By eliminating bearings, the XR850 addresses the primary cause of industrial encoder failures, keeping your critical operations running smoothly.

- Fits NEMA 8.5″ Flanges

- Fits Shafts up to 4 1/2″ [115mm]

- ATEX/IECEx Rated for Zone 1, 2, 21 & 22 Applications

- Ideal for Oil and Gas Drilling

- No Bearings to Wear Out

- Up to 5000 PPR

- Self-Diagnostic LED and Alarm Output

- 3 Year No-Hassle Warranty

- cULus Class I Division 1 Groups A,B,C,D Listed

- cULus Class I Zone 0 Group IIC

- cULus Class I Division 2 Groups A,B,C,D Listed