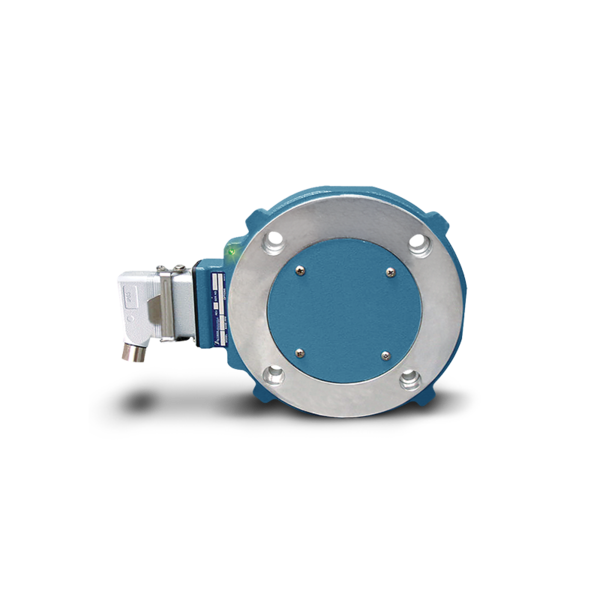

XR85A

Built for Durability in Hazardous Environments

The XR85A SMARTSafe™ 8.5″ Magnetic Encoder redefines hazardous duty performance with its modular, no-bearing construction. Certified for ATEX and UL applications, it is designed to operate reliably in gas and ATEX dust hazardous environments.

The XR85A eliminates the need for barriers, isolators, or explosion-proof glands in Level 2 settings, making it a dependable choice for industries like paint booths, draw works, and coil tubing rigs. Built to withstand vibration, shock, liquids, dust, and dirt, the XR85A outperforms traditional encoders in harsh industrial conditions.

For Level 1 applications, the XR85A pairs seamlessly with XRB1 or XRB2 isolators, allowing intrinsically safe wiring and eliminating the need for costly explosion-proof conduit. Unlike optical encoders with fragile bearings, the XR85 mounts directly onto your main application shaft, delivering unparalleled durability.

SMARTSafe™ technology offers protection against short circuits and wiring faults, ensuring continuous operation 24/7. By removing bearings, the XR85A tackles the leading cause of encoder failures, ensuring your critical operations remain uninterrupted.

- Replaces BEI H38 and Dynapar X25 explosion-proof encoders

- Eliminates large & costly flange adapters & flowerpots

- Fits shafts 0.500″ – 3.188″ [10 – 85 mm]

- Thin profile reduces overall motor depth

- No air gap adjustment required

- Shrugs off dirt, oil, and water contamination

- No glass disks to break or optics to fail

- 4,500,000+ hour MTBF design