Our Power Slip Rings Ensures Seamless Power and Data Transmission

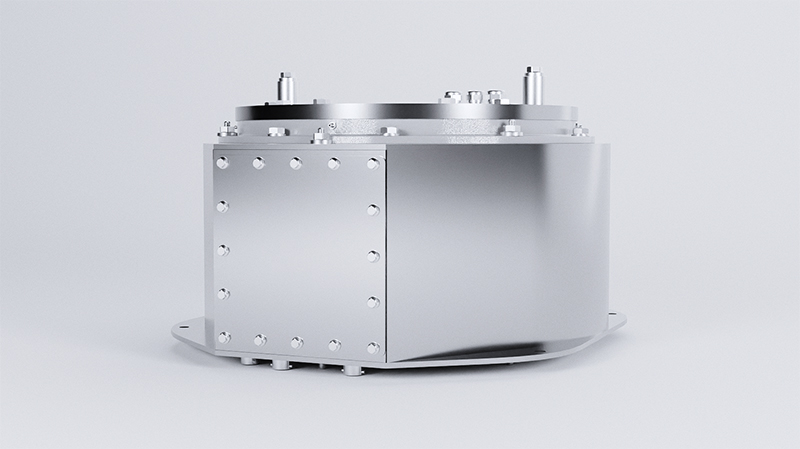

The slip ring is a crucial component in any rotating application where uninterrupted transmission of power, data, and signals is essential. At Penlink, we prioritize reliability and performance. Our slip rings ensure continuous and efficient operation, even in demanding environments.

With extensive experience in designing large slip rings, some exceeding 3 meters in height, we meet the highest standards of quality and precision. Our advanced materials and manufacturing techniques create robust and efficient slip rings that withstand harsh conditions, including extreme temperatures, high humidity, and corrosion.

Our custom-designed slip rings are versatile and tailored to meet the specific needs of applications such as deck machinery, heavy cranes, and winches. Our solutions reduce downtime and enhance the performance and longevity of your systems.

High-Performance Slip Rings for Power and Signal Transfer in Extreme Environments

Our High Power Slip Ring offers a flexible foundation that can be modified to meet the unique demands of various applications, from mining and construction to heavy-duty robotics and marine environments.

Whether adapting for higher power requirements, harsher environmental protection, or specialized compact configurations, we collaborate closely with customers to tailor each solution. This modification capability ensures that our slip rings deliver consistent, reliable performance, maximizing operational efficiency across a diverse range of industries.

- Construction Equipment

- Offshore Drilling Rigs

- Electric Mining Trucks and Loaders

- Tunnel Boring Machines (TBMs)

- Forestry Machinery

- Railway Maintenance Equipment

- Agricultural Machinery

- Dredging Equipment

FAQ

What is a power slip ring and when is it needed?

A power slip ring (or high power slip ring) is designed to transmit large electrical currents between stationary and rotating components. It’s essential in heavy-duty applications like cranes, stackers, reclaimers, and rotary platforms where continuous rotation and high current loads are required.

What makes Penlink’s high power slip rings suitable for harsh environments?

Penlink’s slip rings are built with stainless steel 316 housings, IP54 or higher protection, and EMC shielding. These features ensure resistance to dust, moisture, salt, and vibration, making them ideal for demanding industrial settings.

Can Penlink slip rings transmit both power and data simultaneously?

Yes. Penlink’s modular slip ring systems support simultaneous transmission of high current and complex signals such as Ethernet, Profibus, CANBus, encoder signals, and even fiber optics through integration of fiber optical rotary joint.

How does Penlink ensure that their slip rings operate reliably in harsh conditions?

We use IP-rated enclosures, EMC shielding, and durable contact materials. All components are tested for torque, dielectric strength, and insulation to ensure dependable operation.

How does Penlink customize its slip rings to meet specific customer requirements?

We begin each project with a thorough analysis of the customer’s needs and tailor the slip ring configuration accordingly. This includes mechanical constraints, electrical specifications, and environmental factors.

What types of signals and data can be transmitted through slip rings?

Slip rings can transmit various types of signals and data, including Ethernet, Profibus, CANBus, and fiber optic signals.

What tests are performed on slip rings to ensure their durability and reliability?

Slip rings are tested for insulation resistance, dielectric strength, shock, vibration, and humidity. Third-party inspections can also be arranged if needed.

What maintenance is required for Penlink slip rings?

Maintenance should be performed every 6 to 12 months, depending on the operating environment. It includes visual inspection, cleaning of power rings and brushes, and checking for signs of overheating or wear. Detailed procedures are outlined in Penlink’s operation manuals.

What industries benefit most from Penlink’s high power slip rings?

Industries such as material handling, marine and offshore, defense, and energy rely on Penlink’s slip rings for reliable power and signal transmission in rotating systems.

Solutions Designed For

Your Application

Work with a sales team that has extensive experience in developing solutions for a wide range of applications. We will guide you through the thought process, assist with the design, and deliver a complete solution ready for installation in your machine.

Slip Ring for Electrification of Excavators

Penlink’s high-voltage slip ring solution is designed to meet the power transmission demands of modern electrified excavators. With a rating of 2x200A (800VDC) and 1x200A PE, it ensures reliable electrical transfer even in high-voltage applications. Built with robust materials like SS304 stainless steel and featuring an IP54 sealing degree, this slip ring delivers consistent performance in harsh environments.

Winch Slip Ring for Marine Operations

This slip ring is expertly engineered for offshore operations, seamlessly transmitting power and Ethernet signals to an ROV. Integrated with a swivel, it provides air and water for the robotic system. With high-powered transmission capabilities of 2x800A at 120V, and a robust swivel delivering air at 140 bar and water at 88 bar, our slip ring guarantees unmatched reliability and efficiency.

Slip Ring for Factory Automation

This slip ring integrates seamlessly into Vertical Lay-up Machines capable of holding interchangeable baskets with payload capacities of 250, 500, or 750 tons. Its performance ensures reliable operation in heavy-duty applications where power and data must be transferred smoothly. Our slip rings are engineered to meet the demands of modern manufacturing processes, ensuring consistent performance over time.

Slip Ring for Large Offshore Crane

This slip ring features a three-chamber design, standing at 3.4 meters tall. Each motor’s rings are housed in separate chambers to prevent power transmission shortages, enabling a continuous current of 2000A x 3, 930V, and a 75kVA short circuit rating. For signal transmission, we utilized fiber brush technology, ensuring power and signal transfer without debris. The optical slip ring includes 10 independent channels and operates without external power.

Ready to Enhance Your Applications with our High Power Slip Rings?

Get in touch with us to learn more about the possibilities when choosing a Penlinks High Power Slip Ring. We have extensive knowledge in various applications that require significant power, signals, and data transfer.

By working with Penlink, you will gain deeper insights into your application, and the solution we design will enhance the overall end-user experience.